How to Reduce Aluminum Casting Costs

Author: SAIVS Date Published: Aug 26,2024

Aluminum Casting is a versatile manufacturing process used to create a wide range of products. However, high costs can often be a barrier to entry. To optimize your aluminum casting process and reduce overall costs, consider these key strategies:

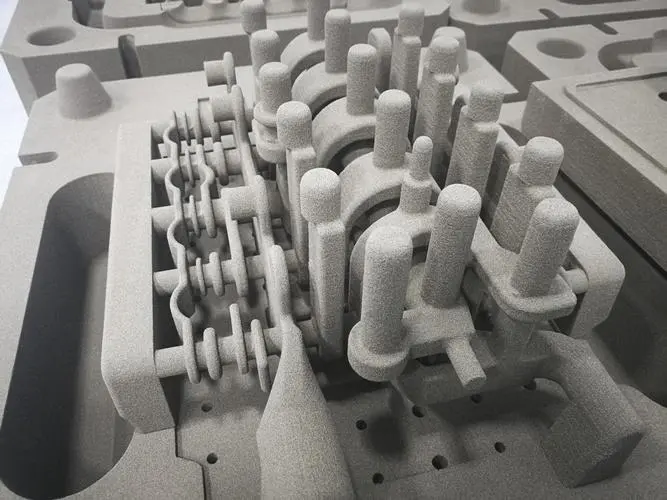

1. Design for Manufacturability

Simplify geometry: Reducing the complexity of your part can significantly decrease machining time and material waste.

Consolidate features: Combining multiple features into one can streamline the casting process.

Optimize wall thickness: Consistent wall thickness helps prevent defects and reduces material usage.

Consider casting simulations: Using computer-aided engineering (CAE) can identify potential issues early in the design process and prevent costly rework.

2. Select the Right Alloy

Match alloy to application: Choosing an alloy with properties that meet the specific requirements of your part can prevent over-engineering and unnecessary costs.

Consider recycled alloys: Recycled aluminum alloys offer cost savings and can be just as strong as virgin alloys.

Evaluate alloy availability: Ensure the alloy you choose is readily available to avoid supply chain disruptions and price fluctuations.

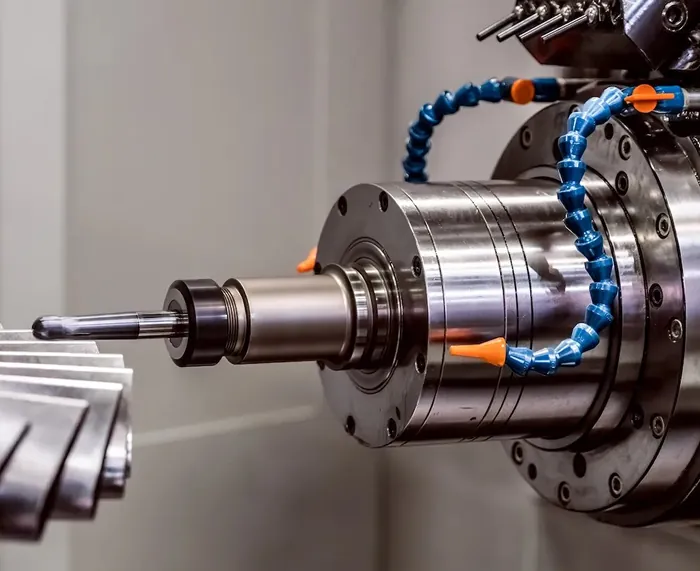

3. Optimize Casting Process Parameters

Fine-tune pouring temperature: The correct pouring temperature can improve fill, reduce porosity, and enhance mechanical properties.

Adjust cooling rates: Controlling the cooling rate can affect the microstructure and mechanical properties of the casting.

Minimize defects: Implementing Quality Control measures can reduce the number of defective castings and associated costs.

4. Utilize Recycled Aluminum

Environmental benefits: Recycling aluminum significantly reduces energy consumption and greenhouse gas emissions.

Cost savings: Recycled aluminum is often less expensive than virgin aluminum.

Quality assurance: Ensure that recycled aluminum meets your specific quality requirements.

5. Implement Lean Manufacturing Principles

Identify waste: Conduct a value stream mapping exercise to identify and eliminate waste in your casting process.

Reduce setup times: Minimizing setup times can increase production efficiency.

Improve flow: A smooth flow of materials and information can reduce lead times and costs.

Continuous improvement: Implement a culture of continuous improvement to identify and address ongoing challenges.

Conclusion

By following these strategies, manufacturers can significantly reduce the costs associated with aluminum casting. By optimizing design, selecting the right alloy, fine-tuning process parameters, utilizing recycled aluminum, and implementing lean manufacturing principles, businesses can improve their bottom line and gain a competitive advantage.

Why Choose SAIVS™ as Your Supplier?

1.Superb Quality Control Management

At SAIVS, we take pride in our perfect quality management systems and procedures, which guarantees the excellent performance of all our producs, being a professional Investment Casting | Die Casting| Sand Castingmanufacturer in China.

2.Rich Production Experience

With 20 years of experience in production, SAIVS has a deep understanding of the market and trends, and strives for continuous research and innovation. This has created advantages in both the product's performance and appearance.

3.Competitive Prices

As a Chinese factory committed to becoming the most cost-effective Investment Casting | Die Casting| Sand Castingexporter in China, SAIVS provides high-quality products at advantageous prices. By lowering costs and increasing efficiency, we ensure that our customers receive the best possible value for their investment.

4.Perfect After-sales Service

At SAIVS, we strive to provide superior customer service that meets and exceeds expectations. We are always available for any questions or concerns you may have, and we stand by our commitment to providing excellent after-sales support.

Related Posts

-

Factors Affecting the Dimensions of Stainless Steel Castings

Learn about the factors affecting dimensional accuracy, including material expansion and deformation, and understand why choosing an experienced foundry like SA...

-

The Effective Uses of Sand Casting for Construction Machinery Parts

The construction machinery industry requires the production of big parts that have shapes, sizes, and complexities that are not easy to produce by conventional ...

-

A Comprehensive Guide to Customized Food Machinery Parts: Manufacturers, Suppliers, and Prices

People are often interested in a variety of parameters and information when searching for Food Machinery Parts that are customized, factory-made, and available ...

-

Optimizing Tool Materials for Efficient Cast Iron Machining

In the competitive landscape of the machinery industry, improving processing technology and increasing efficiency are crucial for reducing overall costs. O

-

Die cast product design: 3 considerations

Die casting is a manufacturing process used to produce metalcomponents with high precision and efficiency. It involves injecting molten metal into a die, which ...

-

How to improve the quality of gear forgings

How to improve the quality of gear forgings? Shanghai Zhiyuan Flange Forging Co., Ltd. pointed out that hardness is an important quality inspection index for he...