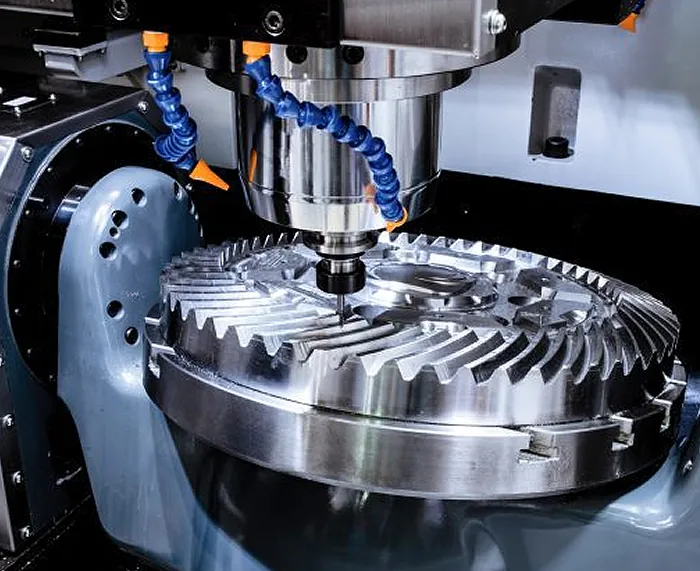

How to Maximize the Efficiency of CNC Machining

Author: SAIVS Date Published: Apr 14,2025

CNC machining efficiency plays a crucial role in optimizing productivity and reducing costs.

Here are some effective ways to improve CNC machining efficiency:

1. Equipment Upgrades and Retooling:

Regularly upgrading or retooling CNC Machinery is essential to stay up-to-date with new technologies and features.

Obsolete equipment can hinder efficiency, so it's important to invest in modern equipment that offers

improved performance and capabilities. Periodic maintenance is also necessary to

prevent major issues and keep the machinery in optimal condition.

2. Operational Optimization:

Maximizing overall throughput requires keeping CNC machines operational and minimizing idle time.

Machines that are frequently idle may experience reduced functionality or performance over time.

By ensuring continuous operation and minimizing downtime, efficiency can be maximized.

3. Power Consumption Management:

Understanding power consumption requirements is crucial to prevent damage

from issues like overheating or short circuits. Upgrading to energy-efficient technologies

can help reduce power consumption, leading to cost savings and improved efficiency.

4. Automated Processes and Load Cells:

Implementing automated processes and utilizing load cells and sensors can reduce

human intervention and increase productivity. By establishing multiple modes of operation,

machine outcomes and efficiency can be maximized while freeing up workers to focus on more valuable tasks.

5. Proactive Maintenance:

Moving from reactive to proactive maintenance strategies can significantly improve efficiency.

Real-time monitoring and preventative maintenance methods, such as automated testing tools

and advanced data monitoring solutions, help identify errors at an early stage and allow for timely intervention.

This proactive approach minimizes downtime and maximizes efficiency.

6. Tool Wear and Thermal Deformation:

Reducing tool wear and managing thermal deformation during the machining process can enhance accuracy and efficiency.

Factors such as machining time, environmental temperature, cutting speed, and feed can affect thermal errors.

By optimizing these parameters and using appropriate cooling techniques, the efficiency of CNC machinery can be improved.

By implementing these strategies, manufacturers can enhance CNC machining efficiency,

increase productivity, reduce costs, and maintain a competitive edge in the industry.

Why Choose SAIVS™ as Your Supplier?

1.Superb Quality Control Management

At SAIVS, we take pride in our perfect quality management systems and procedures, which guarantees the excellent performance of all our producs, being a professional Investment Casting | Die Casting| Sand Castingmanufacturer in China.

2.Rich Production Experience

With 20 years of experience in production, SAIVS has a deep understanding of the market and trends, and strives for continuous research and innovation. This has created advantages in both the product's performance and appearance.

3.Competitive Prices

As a Chinese factory committed to becoming the most cost-effective Investment Casting | Die Casting| Sand Castingexporter in China, SAIVS provides high-quality products at advantageous prices. By lowering costs and increasing efficiency, we ensure that our customers receive the best possible value for their investment.

4.Perfect After-sales Service

At SAIVS, we strive to provide superior customer service that meets and exceeds expectations. We are always available for any questions or concerns you may have, and we stand by our commitment to providing excellent after-sales support.

Related Posts

-

Conquering Casting Shrinkage: A Guide to Flawless Metal Parts

This article explores types of shrinkage, and solidification, and how to control them for high-quality castings.

-

Limitations of CNC Machining

Explore the key limitations of CNC machining. Understand how these factors impact manufacturing efficiency and part quality.

-

Safeguarding Product Reliability: Penetrant Testing and Ultrasonic Flaw Detection for Castings

This article delves into casting defects, their impact on product quality, and two key non-destructive testing methods: penetrant testing (PT) and ultrasonic fl...

-

Why SAIVS is Your Trusted Partner for Advanced Precision Casting

IntroductionPrecision casting is a manufacturing process that uses a mold to create a metal part. The mold is made of a material that is easily melted, such as ...

-

High-quality Heat Resistant Steel Casting from China Manufacturer

Heat resistant steel casting refers to a type of casting that can withstand high temperatures, making it ideal for use in environments where extreme heat is pre...

-

Investment Casting: Freedom in Design with Minimal Draft Angles

This article explores the concept of draft angles, their role in casting processes, and how investment casting overcomes this limitation, enabling the creation ...