How digital microscopy can optimize the sand casting process

Author: SAIVS Date Published: Sep 23,2024

Sand Casting is an important process for manufacturing metal parts, but the quality of castings is often affected by various defects. Common defects include shrinkage, porosity, cracks, and so on. These defects not only affect the appearance of castings, but also reduce their mechanical properties, and even lead to product scrap. In this paper, we will discuss the common defects in sand casting in depth, and analyse the reasons for their formation and preventive measures.

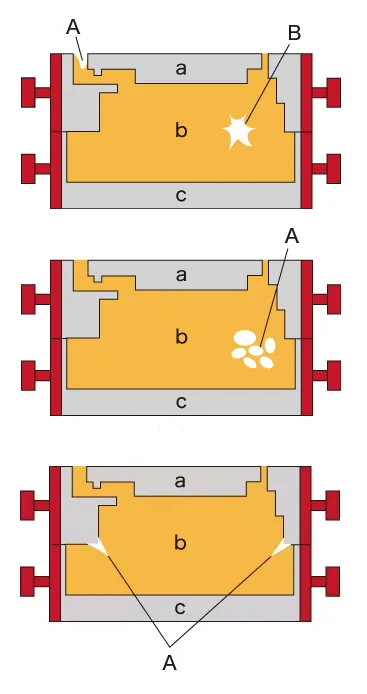

Shrinkage Hole

A shrinkage hole is a casting sand eye, usually found inside the casting. Its formation is mainly caused by the volume contraction of liquid metal during solidification. Shrinkage holes have complex shapes and may affect the mechanical properties and appearance of the casting. External shrinkage refers to the surface shrinkage of the casting. In contrast, internal shrinkage refers to cavities formed on the inside of the casting, and these defects may require subsequent machining to repair.

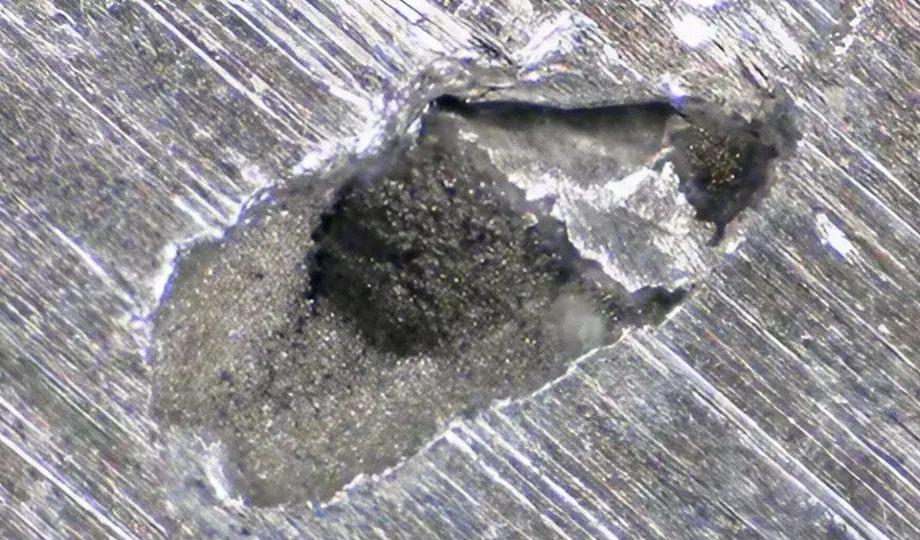

Porosity

Pneumatic holes are defects with round cavities in the casting, formed when air and other gases are drawn into the molten metal during the casting process. These gases do not escape in time and remain inside the casting after solidification, resulting in porosity. Porosity not only affects the appearance of the casting but may also affect its strength and sealing, leading to problems in use.

Cracking

Cracking refers to cracks on the surface of the casting, which are usually caused by volumetric shrinkage of the metal as it cools during the casting process, as well as internal stresses. The presence of cracks can seriously affect the serviceability of the casting, especially when subjected to high pressures or loads. Prevention of cracking usually requires control of casting process parameters such as temperature and cooling rate.

Insufficient flow

Insufficient flow is the failure of the molten metal to fill the mold, resulting in an incomplete casting shape. This defect may affect the dimensional accuracy and shape of the casting and is common in castings with complex shapes. Improvements to the casting process or adjustments to the Mold design can effectively reduce the problem of insufficient flow.

Burrs

Burrs are tiny metal protrusions on the joint surfaces of the casting molds, which are usually caused by increased gaps due to poor accuracy of the molds, incorrect assembly, or aging of the molds. Burrs not only affect the appearance of the casting but can also cause difficulties in subsequent machining and therefore need to be removed in post-processing.

Dimensional defects

Poor dimensions are deviations between the actual dimensions of the casting and the design dimensions. This is usually due to inaccurate estimation of volume shrinkage and deformation during the casting process, or poorly sized and improperly assembled molds. Ensuring the accuracy of the mold and correct estimation can effectively reduce the occurrence of poor dimensions.

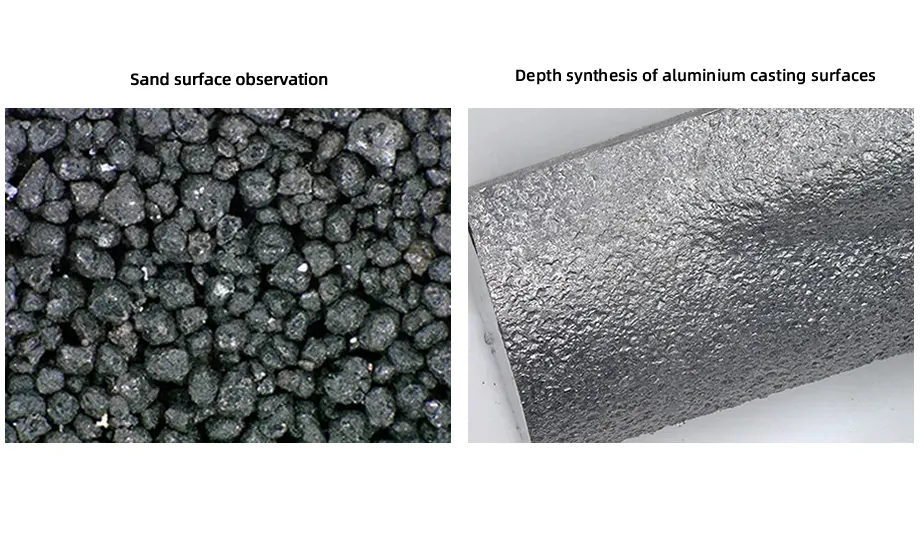

Poor casting surface

Poor casting surface is usually caused by melting and sintering of the sand portion on the surface of the casting mold. Surface defects not only affect the aesthetics of the casting but may also affect its corrosion resistance and adhesion. Regular inspection and maintenance of the mold surface, as well as optimization of casting conditions, can reduce the occurrence of such defects.

Example: Analyzing Porosity in Sand Castings Using a Digital Microscope

Conclusion

In conclusion, the quality of a casting is significantly influenced by various defects that can arise during the casting process. Common defects include shrinkage holes, porosity, cracking, insufficient flow, burrs, dimensional defects, and poor casting surface. Understanding the causes and consequences of these defects is crucial for implementing effective measures to prevent or minimize their occurrence. By carefully controlling process parameters, optimizing mold design, and utilizing advanced inspection techniques, it is possible to produce high-quality castings that meet the desired standards.

Why Choose SAIVS™ as Your Supplier?

1.Superb Quality Control Management

At SAIVS, we take pride in our perfect quality management systems and procedures, which guarantees the excellent performance of all our producs, being a professional Investment Casting | Die Casting| Sand Castingmanufacturer in China.

2.Rich Production Experience

With 20 years of experience in production, SAIVS has a deep understanding of the market and trends, and strives for continuous research and innovation. This has created advantages in both the product's performance and appearance.

3.Competitive Prices

As a Chinese factory committed to becoming the most cost-effective Investment Casting | Die Casting| Sand Castingexporter in China, SAIVS provides high-quality products at advantageous prices. By lowering costs and increasing efficiency, we ensure that our customers receive the best possible value for their investment.

4.Perfect After-sales Service

At SAIVS, we strive to provide superior customer service that meets and exceeds expectations. We are always available for any questions or concerns you may have, and we stand by our commitment to providing excellent after-sales support.

Related Posts

-

Understanding Surface Roughness in CNC Machining

Learn about its importance, measurement, and impact on CNC machined parts, and explore various surface finishes and their applications.

-

Investment Casting: Freedom in Design with Minimal Draft Angles

This article explores the concept of draft angles, their role in casting processes, and how investment casting overcomes this limitation, enabling the creation ...

-

Problems in quality control of aluminum die castings

China's die-casting industry has continuously developed and applied new technologies and materials, which can also be seen everywhere in life. The character...

-

Heat Treatment of Stainless Steel

Heat Treatment of Stainless SteelStainless steel is one of the most widely used alloys in metal casting — prized for its strength, hardness, and resistance to c...

-

3 Casting Types of Corrosion Resistant Metals

In the world of metal casting, different metals and alloys have varying resistance to corrosion. Selecting the perfect material for your project is a critical d...

-

Die Casting Temperature Control: Improve Casting Quality and Production Efficiency

Die casting mold temperature affects casting quality and productivity. Learn how to control temperature for optimal casting.