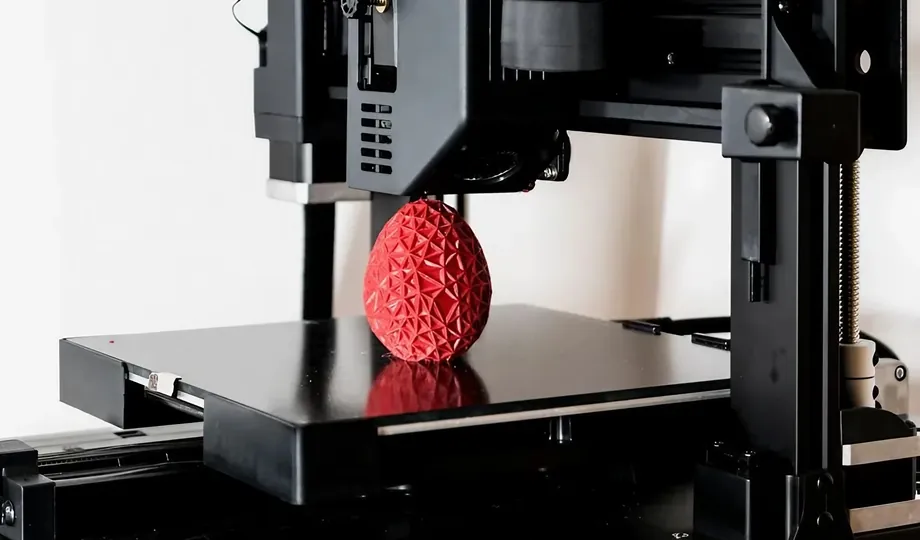

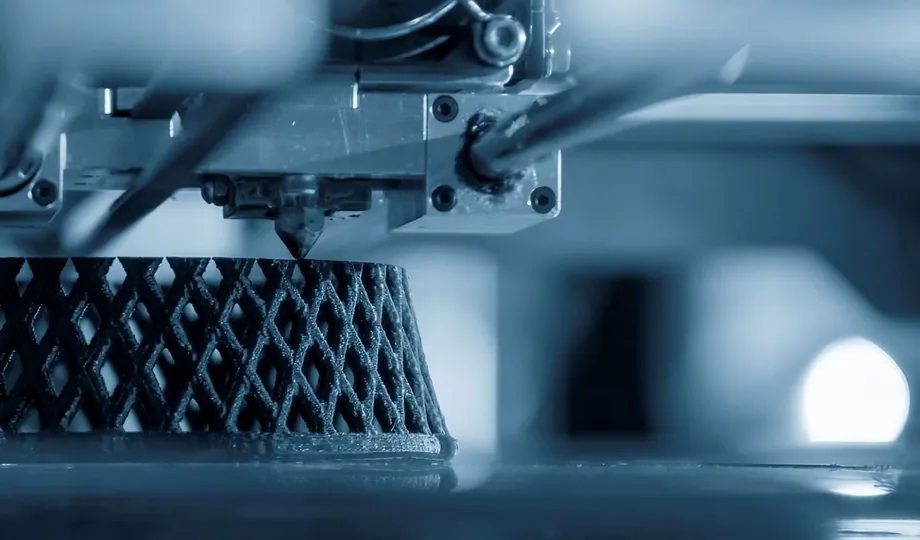

How Printing Choices and Design Enhance the Strength of Your 3D Prints

Author: SAIVS Date Published: Apr 01,2024

This passage discusses factors that influence the tensile strength of 3D printed parts.

Tensile strength refers to a material's ability to withstand pulling forces without breaking. Here's a breakdown of the key points:

Factors Affecting Tensile Strength:

material selection:

Different materials have varying inherent strengths. Popular choices include ABS (strong and flexible), PLA (rigid but brittle), and metals (exceptionally strong).

Printing Parameters:

Settings like layer height, infill density, print speed, and temperature significantly impact strength.

Higher infill densities create stronger parts but increase material usage and print time.

Lower layer heights improve layer adhesion and strength but take longer to print.

Proper printing temperature ensures good material flow and adhesion for strong parts.

Part Design:

The design itself influences strength. Factors include:

Geometry: How the part is shaped affects how it distributes stress.

Orientation: Parts tend to be weaker along the printing direction (z-axis) due to layer bonding.

Features: Design elements like ribs and specific shapes can enhance strength.

Post-Processing: Techniques like annealing (heat treatment) can improve strength by reducing internal stresses and strengthening layer adhesion.

How To Increase 3D Printed Tensile Strength:

Techniques such as annealing, coating, and fiber reinforcement offer avenues for enhancing the mechanical properties of 3D printed parts.

Annealing involves heat treatment to relieve residual stresses and improve strength and stability.

Coatings provide protective layers that enhance strength, resistance, and other properties.

Fiber reinforcement integrates high-strength fibers into polymer matrices, resulting in exceptional strength and durability.

Additional Points:

The strength of 3D printed parts is often anisotropic, meaning it can vary depending on the direction of force due to the layering process.

3D printed parts can be stronger than traditionally manufactured parts in specific scenarios, especially with complex, optimized designs.

Testing methods like tensile tests, compression tests, and impact tests are crucial for evaluating the strength of 3D printed parts.

Overall, understanding these factors allows for optimizing the 3D Printing process to create parts with the desired strength for their specific applications.

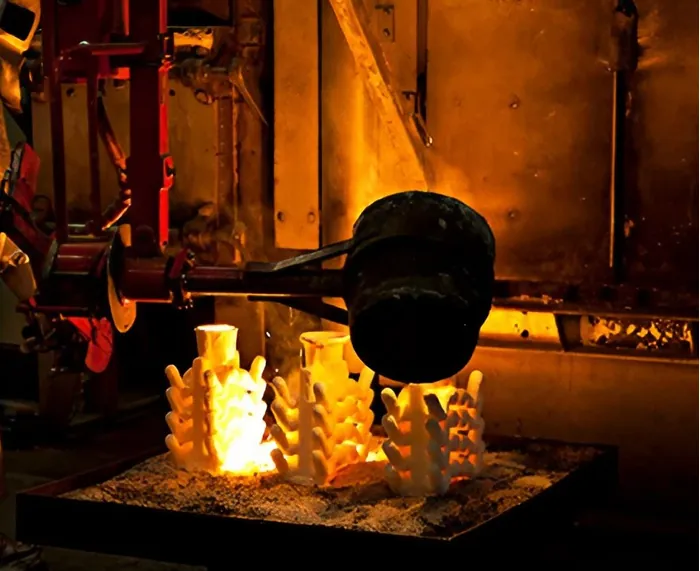

Why Choose SAIVS™ as Your Supplier?

1.Superb Quality Control Management

At SAIVS, we take pride in our perfect quality management systems and procedures, which guarantees the excellent performance of all our producs, being a professional Investment Casting | Die Casting| Sand Castingmanufacturer in China.

2.Rich Production Experience

With 20 years of experience in production, SAIVS has a deep understanding of the market and trends, and strives for continuous research and innovation. This has created advantages in both the product's performance and appearance.

3.Competitive Prices

As a Chinese factory committed to becoming the most cost-effective Investment Casting | Die Casting| Sand Castingexporter in China, SAIVS provides high-quality products at advantageous prices. By lowering costs and increasing efficiency, we ensure that our customers receive the best possible value for their investment.

4.Perfect After-sales Service

At SAIVS, we strive to provide superior customer service that meets and exceeds expectations. We are always available for any questions or concerns you may have, and we stand by our commitment to providing excellent after-sales support.

Related Posts

-

Differences between Die Casting and Investment Casting

What does investment casting mean?Investment casting is also called lost wax casting or dewaxed casting. Making parts by investment casting is usually a more ti...

-

The Excellence of Sand Casting for Gearbox Housings

Why cast iron gearbox housings made by sand casting are ideal for strength, durability and complex designs.

-

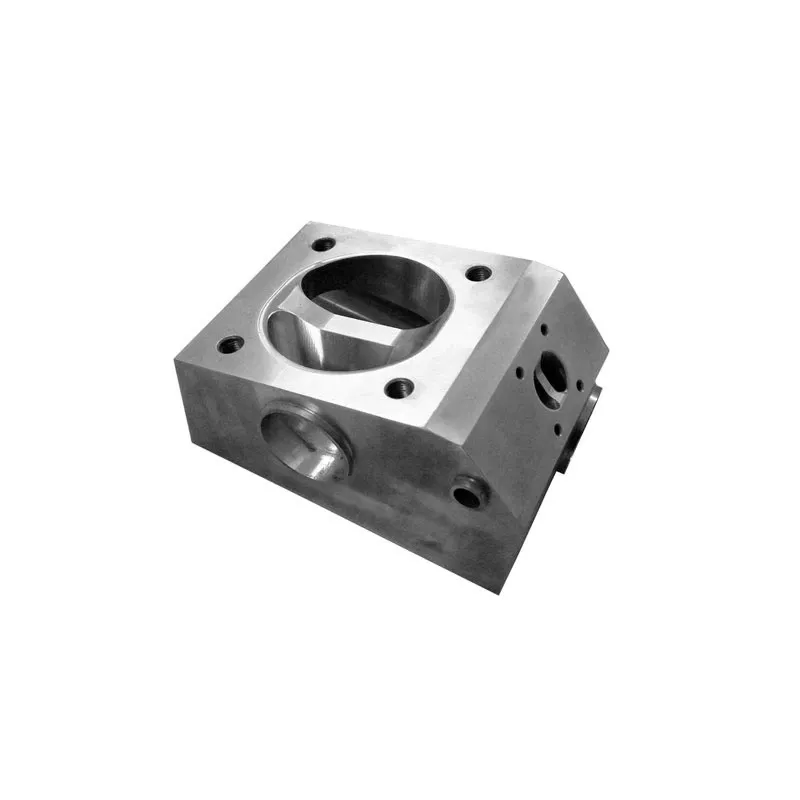

Process of CNC Rapid Prototyping

CNC Rapid Prototyping, also known as CNC-RP, is a process that combines computer numerical control (CNC) machiningwith rapid prototyping techniques to quickly p...

-

How Vacuum Prevents Oxidation in Steel Heating

Introduction:Vacuum furnaces are specialized equipment used in heating processes that take place under low-pressure environments. The unique feature of a v

-

Why Investment Casting Reigns Supreme for Complex Designs and Superior Finishes

Investment casting excels in design flexibility, superior surface finish, ideal for intricate parts in aerospace, automotive, and medical industries.

-

Brief analysis of the characteristics and advantages of aluminum die casting

Briefly analyze some characteristics and advantages of aluminum die casting.Aluminum die casting is a very popular manufacturing method in the process of produc...