Factors Affecting the Dimensions of Stainless Steel Castings

Author: SAIVS Date Published: Oct 21,2024

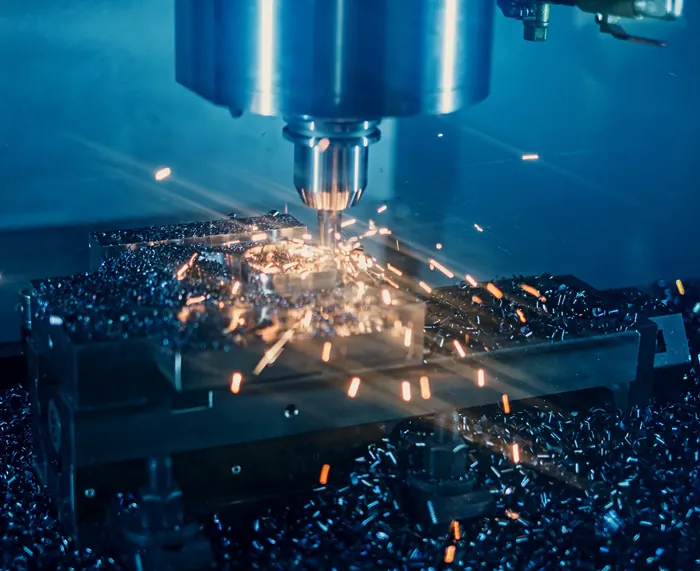

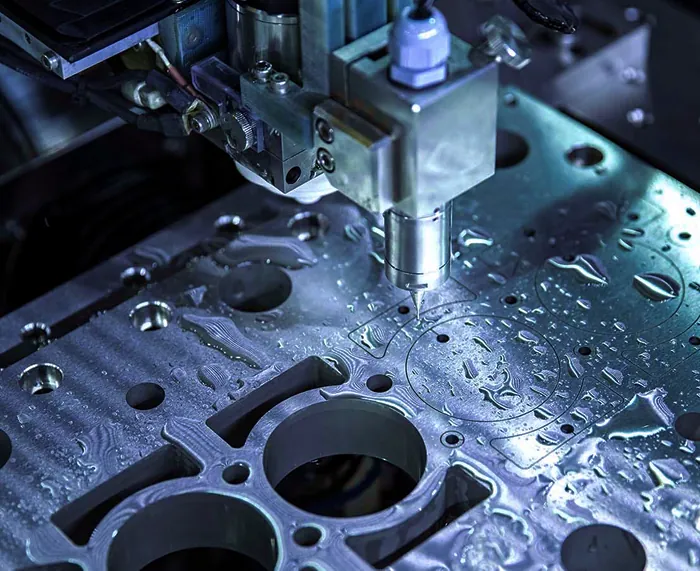

Investment Casting is a method that produces complex-shaped stainless steel castings with precise dimensional tolerances and excellent surface quality. This technique often eliminates the need for further machining, which can be cost-prohibitive or impractical with other methods. While the dimensional accuracy of stainless Steel Castings from investment casting is generally high, various factors can lead to inaccuracies.

Types of Dimensional Inaccuracies

Systematic Inaccuracies: These arise from poor handling, incorrect assembly of wax models, or deviations from prescribed technology. Careful adherence to procedures can often eliminate them.

Random Inaccuracies: These are harder to rectify and can stem from material and design variations, particularly in areas with non-uniform wall thickness.

Key Factors Influencing Dimensional Accuracy

Volume Expansion/Contraction: The materials used—wax, shell, and casting—significantly impact the final dimensions and the precision of the wax model molds.

Deformation of Wax Models: Cooling and storage conditions can affect the wax model's shape.

Shell Deformation: The composition of the shell, along with the methods used for wax model smelting and firing, influences its integrity.

Casting Deformation: Factors such as the casting shape, gating system, and temperatures during the pouring process can lead to dimensional changes.

Deformation is often unavoidable for specialized designs, such as long, thin brackets despite rigorous procedural adherence. For example, a customer, Joey from Australia, submitted a long bracket design. After evaluation, our engineers determined that straightening would be necessary post-casting, as the design inherently predisposed it to deformation.

In conclusion, while many foundries in China offer stainless steel casting services, only experienced companies like saivs can assure consistent quality and accuracy. If you’re seeking reliable stainless steel casting solutions in China, please reach out to us!

Why Choose SAIVS™ as Your Supplier?

1.Superb Quality Control Management

At SAIVS, we take pride in our perfect quality management systems and procedures, which guarantees the excellent performance of all our producs, being a professional Investment Casting | Die Casting| Sand Castingmanufacturer in China.

2.Rich Production Experience

With 20 years of experience in production, SAIVS has a deep understanding of the market and trends, and strives for continuous research and innovation. This has created advantages in both the product's performance and appearance.

3.Competitive Prices

As a Chinese factory committed to becoming the most cost-effective Investment Casting | Die Casting| Sand Castingexporter in China, SAIVS provides high-quality products at advantageous prices. By lowering costs and increasing efficiency, we ensure that our customers receive the best possible value for their investment.

4.Perfect After-sales Service

At SAIVS, we strive to provide superior customer service that meets and exceeds expectations. We are always available for any questions or concerns you may have, and we stand by our commitment to providing excellent after-sales support.

Related Posts

-

Safety Guidelines for Precision CNC Machining

This comprehensive guide covers training, PPE, machine maintenance, proper setup, emergency procedures, and more to ensure a safer and more efficient manufactur...

-

Unlocking Efficiency: How Mold Coatings Minimize Downtime and Maximize Productivity

This guide describes the selection and application of die materials and coatings to help manufacturers extend die life.

-

Comparison of Silica Sol and Water Glass in Precision Casting

This article will explore the characteristics, applications, and advantages of Silica Sol and Water Glass, providing a comprehensive understanding of their role...

-

Why should die casting be used for mechanical parts?

Die-casting process is characterized by low cost, good workmanship, and resolving saves resources and energy. The application and development of this material w...

-

5 CNC Machining Materials

AluminumAluminum is one of the most popular materials for CNC machining due to its excellent machinability, lightweight nature, and resistance to corrosion

-

Unlocking Complexity: How CNC Milling Brings Intricate Designs to Life

From 3D design to the magic of milling, uncover the process and advantages, including high dimensional accuracy and efficiency.