Effective Strategies to Prevent and Solve Subcutaneous Porosity in Castings

Author: SAIVS Date Published: Mar 03,2025

Measures to Prevent and Solve Subcutaneous Porosity in Castings

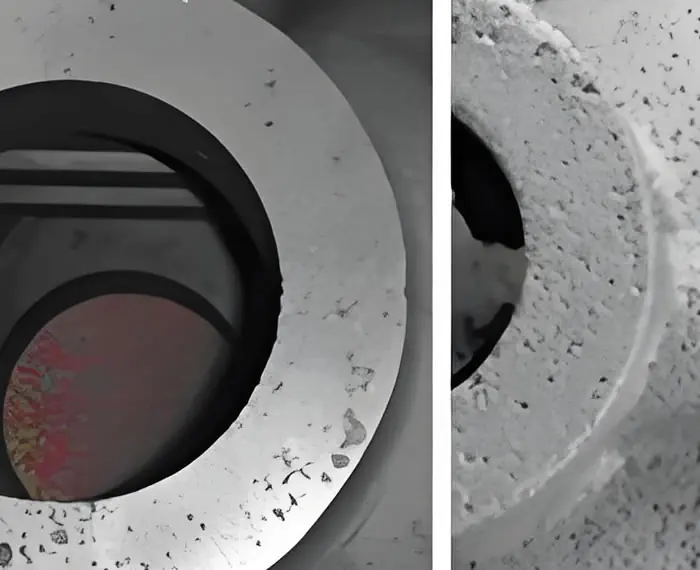

Subcutaneous porosity in castings is a common defect caused by various factors in the casting process.

The formation of pores results from improper handling of materials, smelting, pouring, sand mixing, molding, and core making.

To ensure high-quality castings, strict control over each step is necessary.

This article outlines the critical measures to prevent and resolve subcutaneous porosity in castings.

1. Raw material selection

The quality of raw materials directly affects the formation of pores. It is essential to:

- Avoid using raw materials with high titanium (Ti) and aluminum (Al) content, high-alloy steel, or stainless steel.

- Remove corrosion, oxidation, oil, coal slime, and waste sand from raw materials before use.

- Dry wet and watery raw materials before use.

- Avoid using thin iron sheets (pipe fittings) less than 3mm in thickness.

- Maintain raw material lengths within 300-400mm to ensure uniform melting.

2. Hot metal Smelting

Proper smelting techniques help minimize gas absorption and oxidation, reducing porosity risk:

- Load raw materials compactly to minimize air exposure and oxidation.

- Remove slag 2-3 times during each furnace melt and cover molten iron with insulation materials to prevent oxidation.

- Limit high-temperature waiting time for molten iron to 10-15 minutes to prevent deterioration.

- Maintain a tapping temperature of 1540±10°C and cover molten iron with slag heat-preserving agents.

- Prohibit the use of non-standard recarburizers.

3. Inoculant Control

Proper inoculant handling ensures uniform casting structures:

- Bake inoculants at 300-400°C before use to remove moisture.

- Use inoculants with a particle size of 5-10mm.

- Ensure the aluminum content of inoculants is below 1%.

4. Pouring Process Optimization

Efficient pouring techniques reduce gas entrapment and porosity:

- Thoroughly dry pouring ladles; avoid using wet ladles.

- Increase pouring temperature and follow the "slow-fast-slow" pouring principle.

- Ensure molten iron continuously fills the sprue to establish static pressure and resist gas intrusion.

- Avoid pouring molten iron below 1350°C in small ladles; reheat if necessary.

- Implement effective slag blocking and removal techniques to prevent oxidation.

5. Sand Mixing Control

Proper sand quality and composition are essential for reducing porosity:

- Maintain molding sand moisture below 3.5%.

- Control air permeability between 130-180 and wet compressive strength between 120-140KPa.

- Use High-quality bentonite and coal powder.

- Add new sand periodically to maintain quality.

- Clean excess sand and thoroughly clean sand mixers daily.

6. Molding Process Improvements

Good molding practices help minimize gas formation:

- Equip molds with vent grooves or vents to release gas pressure.

- Add dark gas chambers to molds for better gas evacuation.

- Sprinkle cryolite powder on the runner or sand core after testing effectiveness.

7. Core Making Enhancements

Proper core making ensures gas release and minimizes porosity:

- Keep silica sand moisture below 0.2% and mud content below 0.3%.

- Heat silica sand to 25-35°C before mixing components.

- Use polyisocyanate-based cores within 24 hours to prevent moisture absorption.

- Control triethylamine concentration to avoid excess gas formation.

By implementing these measures, foundries can significantly reduce subcutaneous porosity in castings, ensuring higher quality and structural integrity.

Why Choose SAIVS™ as Your Supplier?

1.Superb Quality Control Management

At SAIVS, we take pride in our perfect quality management systems and procedures, which guarantees the excellent performance of all our producs, being a professional Investment Casting | Die Casting| Sand Castingmanufacturer in China.

2.Rich Production Experience

With 20 years of experience in production, SAIVS has a deep understanding of the market and trends, and strives for continuous research and innovation. This has created advantages in both the product's performance and appearance.

3.Competitive Prices

As a Chinese factory committed to becoming the most cost-effective Investment Casting | Die Casting| Sand Castingexporter in China, SAIVS provides high-quality products at advantageous prices. By lowering costs and increasing efficiency, we ensure that our customers receive the best possible value for their investment.

4.Perfect After-sales Service

At SAIVS, we strive to provide superior customer service that meets and exceeds expectations. We are always available for any questions or concerns you may have, and we stand by our commitment to providing excellent after-sales support.

Related Posts

-

Technical Requirements for Investment Casting

Throughout the production process, precision casting solidifies its liquid immediately at room temperature and pours the compound into its unique die casting di...

-

Choosing the Right Stainless Steel Forging Manufacturer: Key Factors to Consider

Discover applications (construction, medical) and qualities of a good supplier (expertise, customization).

-

Porosity Issues in Aluminum Die Castings: Formation, Types, Effects, and Solutions

This article aims to provide a comprehensive overview of porosity issues in aluminum die castings.

-

Brief analysis of the characteristics and advantages of aluminum die casting

Briefly analyze some characteristics and advantages of aluminum die casting.Aluminum die casting is a very popular manufacturing method in the process of produc...

-

Sandblasting vs. Abrasive Blasting: Understanding the Nuances

Discover the key differences between sandblasting and abrasive blasting, focusing on their applications, health and safety implications, and environmental impac...

-

From Iron Alloys to Aluminum Alloys: Understanding the World of Ferrous and Non-Ferrous Metals

Delve into the world of metals with this comprehensive guide to ferrous and non-ferrous metals. Explore their properties, applications, and key differences.