Die cast product design: 3 considerations

Author: SAIVS Date Published: Nov 02,2023

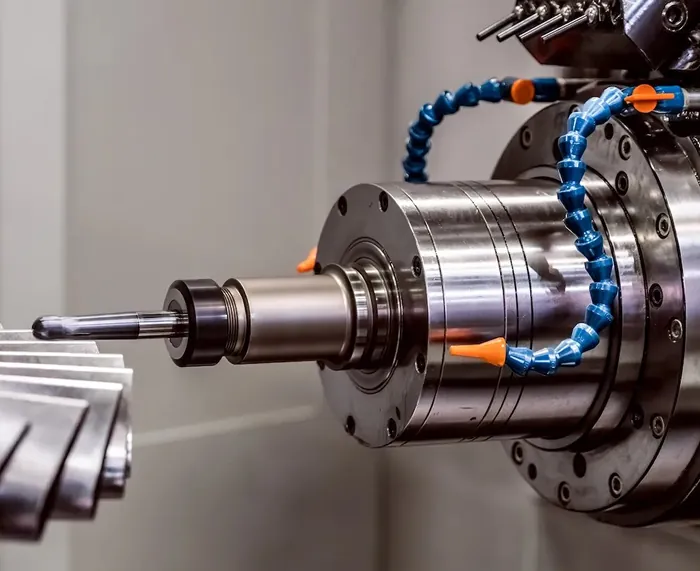

Die Casting is a Manufacturing Process used to produce metal

components with high precision and efficiency.

It involves injecting molten metal into a die,

which is a mold or cavity that gives the desired shape to the final product.

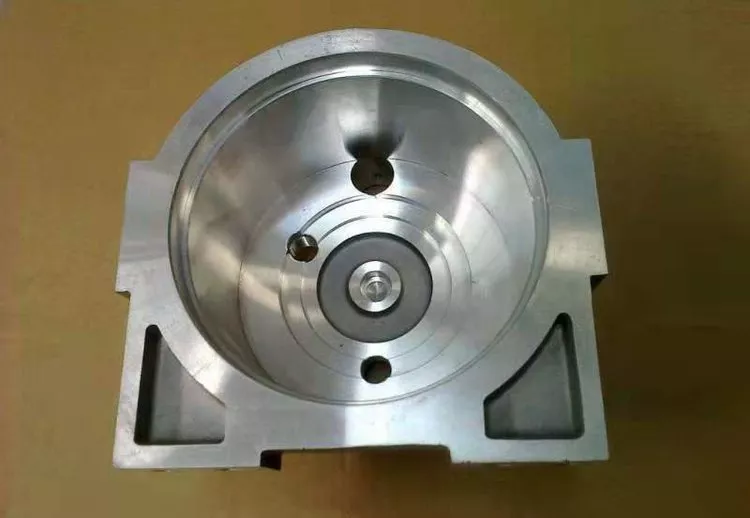

The die is made of two halves, typically referred to asthe "ejector"

and "cover" sides, that come together to form the parting line.

The draft angle refers to the slope or incline on the

walls of a die used in the casting process.

It is determined by the way the die and sliding cores open.

The purpose of the draft angle is to facilitate

the easy removal of the cast from the die.

By allowing the cast to slide out smoothly instead

of sticking to the slides, the process becomes

more efficient and ensures high-quality casting.

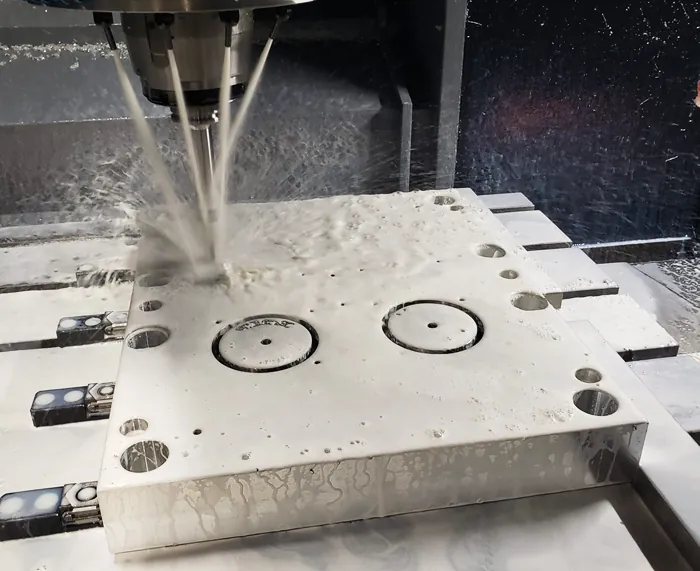

Uniform Wall Thickness:

In die casting, it is important to maintain a consistent

wall thickness throughout the component.

Sudden changes in thickness or geometry can disrupt the

flow of molten metal into the die, leading to the inclusion

of air and resulting in poor surface finish.

Proper calculation and consideration of

the draft angle can help avoid these issues.

Parting Line:

Every component produced through die casting has a parting line,

which is the point where the two halves of the die meet.

The parting line should be indicated on the component's

drawing and should be taken into account during the Die Casting Process.

Critical tolerances related to the parting line should be

specified in relation to one of the specific sides of the die,

namely the "ejector" and "cover" sides.

It is challenging to control critical tolerances

directly on the parting line itself.

Additionally, the parting line should not coincide with a

specific feature of the part, as it may affect the aesthetic appearance.

Calculating the draft angle can help determine

the visibility or concealment of the parting line.

Why Choose SAIVS™ as Your Supplier?

1.Superb Quality Control Management

At SAIVS, we take pride in our perfect quality management systems and procedures, which guarantees the excellent performance of all our producs, being a professional Investment Casting | Die Casting| Sand Castingmanufacturer in China.

2.Rich Production Experience

With 20 years of experience in production, SAIVS has a deep understanding of the market and trends, and strives for continuous research and innovation. This has created advantages in both the product's performance and appearance.

3.Competitive Prices

As a Chinese factory committed to becoming the most cost-effective Investment Casting | Die Casting| Sand Castingexporter in China, SAIVS provides high-quality products at advantageous prices. By lowering costs and increasing efficiency, we ensure that our customers receive the best possible value for their investment.

4.Perfect After-sales Service

At SAIVS, we strive to provide superior customer service that meets and exceeds expectations. We are always available for any questions or concerns you may have, and we stand by our commitment to providing excellent after-sales support.

Related Posts

-

Preventing Flow Lines in Injection Molding

Flow lines, visible as streaks or wave-like patterns on the surface of molded parts, are a common aesthetic defect in injection molding. Although they typi

-

Choosing the Right Aluminum Alloy for Your Project

To understand the factors affecting bendability and the strengths of popular bendable aluminum alloys.

-

How to Prevent Shrinkage in Die Castings

At present, the application of impregnation technology in the products of die-casting aluminum manufacturers is constantly expanding. China advocates for full i...

-

Boost Tundish Life: Key Strategies for Continuous Casting Efficiency

Enhancing Continuous Casting Tundish Life: Key Measures and StrategiesIntroductionThe continuous casting tundish plays a pivotal role in the steel producti

-

Rapid Injection Molding: A Guide to Fast-Track Production

Rapid injection molding offers fast, cost-effective production of plastic parts in low to medium volumes. Learn about the process, advantages, disadvantages, an...

-

Factors Affecting the Dimensions of Stainless Steel Castings

Learn about the factors affecting dimensional accuracy, including material expansion and deformation, and understand why choosing an experienced foundry like SA...