Die Casting Quality: How to Master Materials?

Author: SAIVS Date Published: Mar 24,2025

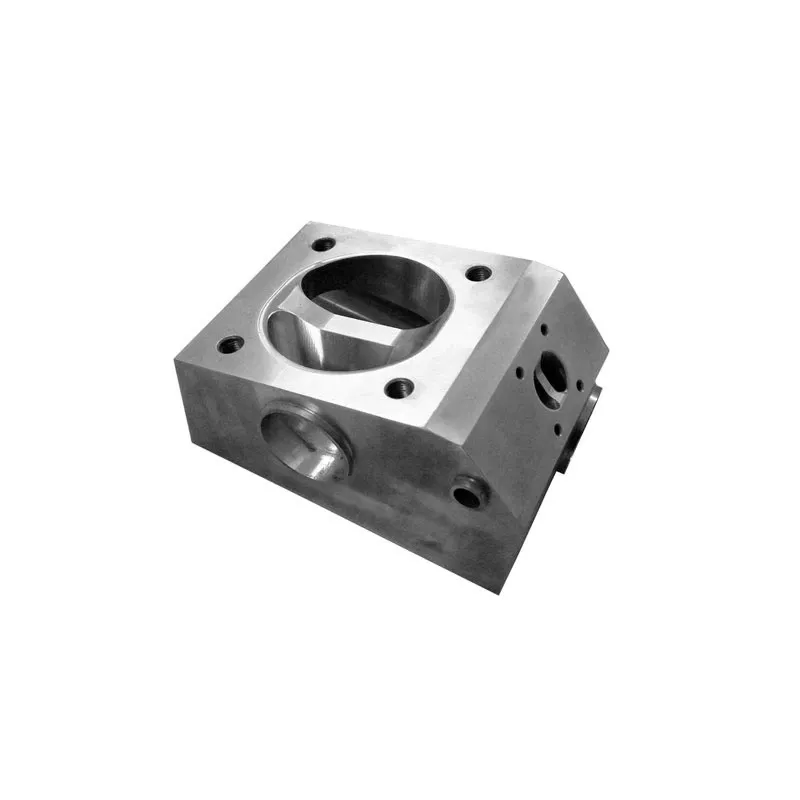

In the intricate domain of Die Casting production, the pursuit of unparalleled product quality necessitates a comprehensive and meticulous approach to aluminum alloy and auxiliary material management.

At Ningbo saivs Machinery Co., Ltd., we recognize that achieving superior die casting outcomes transcends the mere deployment of advanced machinery; it demands a profound understanding of material science, process control, and a relentless commitment to precision.

This article delves into the critical facets of this management philosophy, illustrating how our expertise translates into tangible advantages for our esteemed clientele.

The Foundational Significance of Aluminum Alloy Ingot Entry Control

The journey towards manufacturing high-caliber die castings commences with the rigorous control of incoming aluminum alloy ingots.

At SAIVS, we prioritize uncompromising inspection protocols upon material arrival.

This encompasses meticulous visual assessments to ascertain surface smoothness, the absence of defects such as oil stains and oxide scales, and meticulous fracture structure analyses to ensure density and the absence of segregation or inclusions.

Furthermore, compositional analysis of each batch is paramount.

We diligently conduct sampling and testing procedures to guarantee alloy qualification, particularly for specialized products that necessitate specific mechanical or airtightness properties.

Our unwavering commitment to preventing alloy mixing through the implementation of clear visual identification and segregated storage protocols ensures the integrity of your final product.

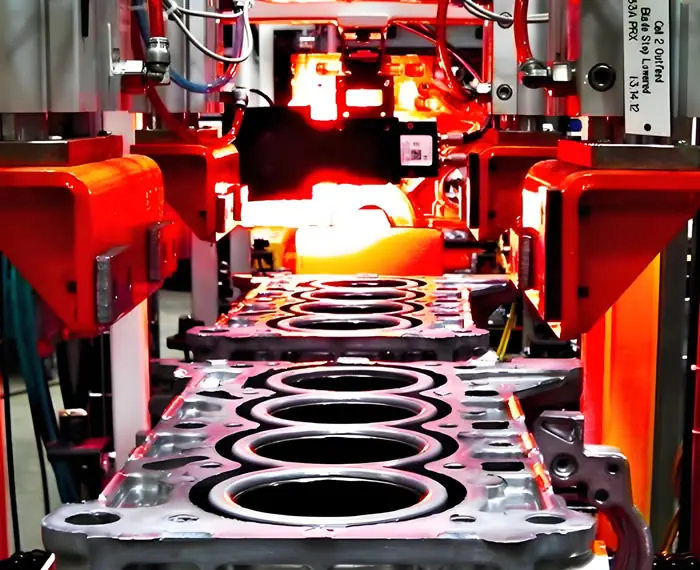

The Art and Science of Aluminum Alloy Melting Process Control

Transforming raw materials into exceptional die castings necessitates the precise control of the melting process.

SAIVS adheres to stringent industry standards, managing raw materials (new, recycled, and auxiliary) with unwavering attention to detail.

Our established protocols dictate precise melting temperatures, smelting times, and recycled material proportions, ensuring process stability and consistency.

We acknowledge the critical importance of recycled material management. At SAIVS, recycled materials undergo rigorous classification and management procedures to prevent contamination.

Oily contaminants are handled by aluminum ingot manufacturers, and scattered aluminum blocks are meticulously cleaned prior to use.

We adapt recycled material proportions based on environmental conditions, ensuring optimal melt quality.

Slagging and degassing procedures are executed promptly, and we maintain meticulous records of process parameters.

Our emphasis on minimizing melt times (within 4 hours) mitigates the risk of increased hydrogen content, safeguarding the strength and airtightness of your die castings.

The Crucial Role of Auxiliary Material Management

Auxiliary materials play a pivotal role in die casting success. SAIVS excels in the management of these materials, maximizing product quality and production efficiency.

- Release Agent Control: The selection and application of release agents are critical. We prioritize agents with high-temperature lubricity, low volatility, non-corrosive properties, and stable performance. Our team is expertly trained in precise spraying techniques, understanding the nuances of timing, dilution ratios, and application volumes. We emphasize the importance of correct release agent to water ratios to avoid issues like gas generation and mold sticking. SAIVS's rigorous management of release agents ensures optimal casting surface quality, mold protection, and extended tool life.

- Punch Oil Management: Lubrication is essential for efficient die casting. At SAIVS, we understand the importance of complete combustion of punch oil after aluminum liquid entry. We carefully monitor the application of punch oil, ensuring proper usage and minimizing residue. Our Quality Control processes include verification methods to ensure the optimal amount of lubrication, preventing defects like porosity.

- Punch Management: The punch-pressure chamber system is vital for die casting. SAIVS is committed to optimizing punch design, manufacturing, and maintenance. We focus on maintaining optimal clearance between the punch and pressure chamber, preventing leakage and wear. Our expertise in punch cooling systems extends punch life and ensures injection process stability, ultimately leading to consistent product quality.

Crucible Management: The integrity of crucibles, especially cast iron, is paramount. SAIVS adheres to strict operating procedures, including proper crucible coating and maintenance, minimizing iron contamination in aluminum alloys. We also emphasize proper drying and preheating of crucibles to maximize their lifespan and minimize production costs.

SAIVS: Your Strategic Partner in Die Casting Excellence

At Ningbo SAIVS Machinery Co., Ltd., we recognize that achieving die casting excellence necessitates more than just advanced machinery.

It demands a profound understanding of material science, process control, and meticulous attention to detail. Our comprehensive approach to aluminum alloy and auxiliary material management ensures that our clients receive high-quality die castings, optimized production efficiency, and a sustainable competitive advantage. contact us today to explore how our expertise can propel your business forward.

Why Choose SAIVS™ as Your Supplier?

1.Superb Quality Control Management

At SAIVS, we take pride in our perfect quality management systems and procedures, which guarantees the excellent performance of all our producs, being a professional Investment Casting | Die Casting| Sand Castingmanufacturer in China.

2.Rich Production Experience

With 20 years of experience in production, SAIVS has a deep understanding of the market and trends, and strives for continuous research and innovation. This has created advantages in both the product's performance and appearance.

3.Competitive Prices

As a Chinese factory committed to becoming the most cost-effective Investment Casting | Die Casting| Sand Castingexporter in China, SAIVS provides high-quality products at advantageous prices. By lowering costs and increasing efficiency, we ensure that our customers receive the best possible value for their investment.

4.Perfect After-sales Service

At SAIVS, we strive to provide superior customer service that meets and exceeds expectations. We are always available for any questions or concerns you may have, and we stand by our commitment to providing excellent after-sales support.

Related Posts

-

What is forging

What Is Forging?Forging is a term that can have different meanings depending on the context. In general, forging refers to the process of shaping metal using lo...

-

Finding Insights Into Various Forging Techniques

Forging is a manufacturing process that involves shaping metal by applying compressive forces. There are several different forging processes, each with its own ...

-

Brief analysis of the characteristics and advantages of aluminum die casting

Briefly analyze some characteristics and advantages of aluminum die casting.Aluminum die casting is a very popular manufacturing method in the process of produc...

-

A Comprehensive Guide to Customized Food Machinery Parts: Manufacturers, Suppliers, and Prices

People are often interested in a variety of parameters and information when searching for Food Machinery Parts that are customized, factory-made, and available ...

-

Complete Guide to Metal Manufacturing Methods: Die Casting, Forging, Machining and More

Comparing Common Metal Manufacturing Processes: Die Casting, Forging, Machining & MoreMetal parts production relies on a variety of manufacturing technique

-

The Importance of Quality Inspection in Large Stainless Steel Casting

The precision casting industry is rapidly evolving, leading to variations in product quality. This inconsistency necessitates rigorous quality inspections,