Comparison of Silica Sol and Water Glass in Precision Casting

Author: SAIVS Date Published: Jul 17,2024

In the realm of precision casting, two widely used adhesives are Silica Sol and Water Glass. These materials play crucial roles in Investment Casting and Sand Casting, respectively. This article will explore the characteristics, applications, and advantages of Silica Sol and Water Glass, providing a comprehensive understanding of their roles in precision casting.

Characteristics of Silica Sol

Silica Sol, also known as colloidal silica, is a dispersion of nano-sized silica particles in water or a solvent. It is a colloidal solution that is odorless and non-toxic. The molecular formula of Silica Sol is SiO2.nH2O, which reflects its composition of silicon dioxide and water. Silica Sol contains a large amount of water and hydroxyl groups, contributing to its unique properties.

Characteristics of Water Glass

Water Glass, or sodium silicate, is a solution of sodium silicate in water. It is also known as saponin and is available in various forms: liquid, solid, and water-quenching. In its liquid state, Water Glass is a colorless, slightly colored viscous liquid. In its solid state, it appears as a colorless, translucent glass block. Water Glass is used as a binder in various applications due to its adhesive properties.

Applications of Silica Sol in Investment Casting

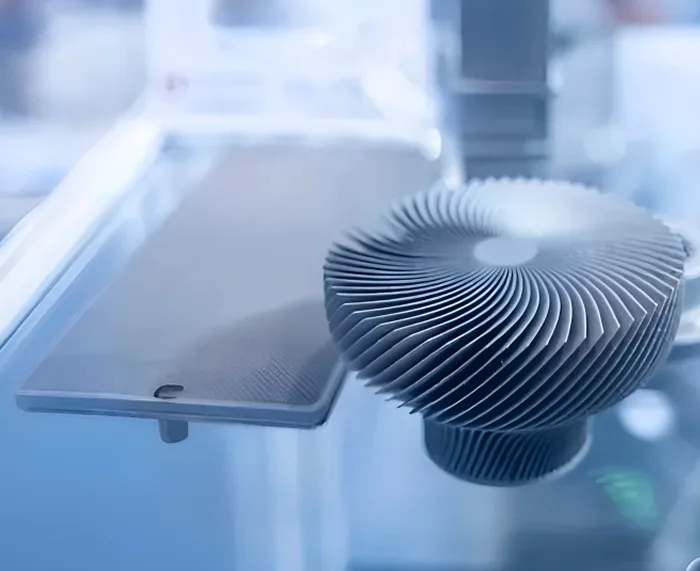

Silica Sol is a critical component in investment casting, also known as lost-wax casting. This precision casting method allows for the production of highly detailed and complex parts with exceptional accuracy and surface quality. The process involves the following steps:

wax pattern Creation: A wax pattern, identical to the final desired part, is produced and attached to a gating system, creating a tree-like assembly.

Dipping: The wax assembly is repeatedly dipped in a Silica Sol slurry and coated with a fine refractory material, such as zircon and fused silica.

Drying: Each layer is allowed to dry before the next dip, forming a multi-layered ceramic shell.

De-Waxing: The assembly is subjected to high temperatures to melt and remove the wax, leaving behind an empty ceramic shell.

Casting: The ceramic shell is preheated, and molten metal is poured into it. The metal solidifies within the ceramic mold.

Shell Removal: After the metal has cooled and solidified, the ceramic shell is removed, revealing the cast metal part.

Advantages of Silica Sol Investment Casting:

High Precision: Produces parts with intricate and precise geometries.

Excellent Surface Quality: Results in smooth and flawless surface finishes.

Complex Designs: Allows for casting of detailed and complex designs.

Disadvantages of Silica Sol Investment Casting:

Cost: More expensive compared to other casting methods.

Production Time: Time-consuming process.

Not Suitable for Smaller Parts: May not be cost-effective for small, simple parts.

Applications of Water Glass in Sand Casting

Water Glass is primarily used as a binder in sand casting, a cost-effective casting method suitable for various applications. The process involves:

Pattern Creation: A pattern, typically made of wood or metal, is created to replicate the shape of the desired product.

Pattern Placement: The pattern is placed within the sand to create an impression, usually in a two-part mold known as a flask.

Sand Preparation: A mixture of sand and Water Glass is prepared. The Water Glass serves as a binder, hardening and adhering to the pattern’s shape.

Mold Formation: The sand mixture is packed around the pattern to form the mold cavity. The flask is then separated into two halves to remove the pattern.

Casting: Molten metal is poured into the mold, filling the cavity left by the pattern.

Solidification: The metal solidifies within the mold, taking on the shape of the pattern.

Mold Removal: After the metal has cooled and solidified, the sand mold is broken away, revealing the cast metal part.

Advantages of Water Glass Casting:

Cost-Effective: Inexpensive material, suitable for casting larger products in large quantities.

Versatility: Can be used for casting a wide variety of product shapes and sizes.

Suitable for Low Melting Point Alloys: Effective for alloys with lower melting points.

Disadvantages of Water Glass Casting:

Surface Finish: Results in rougher surface finishes compared to Silica Sol casting.

Lack of Precision: Less precise, making it unsuitable for applications demanding high precision.

Environmental Concerns: Disposal and waste management challenges due to inorganic binder.

Conclusion

Silica Sol and Water Glass are essential materials in precision casting, each with unique characteristics and applications. Silica Sol is ideal for high-precision, intricate castings with excellent surface quality, despite higher costs and longer production times. Water Glass offers a cost-effective solution for larger, less detailed castings, though it may require additional post-processing for surface finish. Understanding the strengths and limitations of each material helps in selecting the appropriate casting method for specific industrial needs.

Why Choose SAIVS™ as Your Supplier?

1.Superb Quality Control Management

At SAIVS, we take pride in our perfect quality management systems and procedures, which guarantees the excellent performance of all our producs, being a professional Investment Casting | Die Casting| Sand Castingmanufacturer in China.

2.Rich Production Experience

With 20 years of experience in production, SAIVS has a deep understanding of the market and trends, and strives for continuous research and innovation. This has created advantages in both the product's performance and appearance.

3.Competitive Prices

As a Chinese factory committed to becoming the most cost-effective Investment Casting | Die Casting| Sand Castingexporter in China, SAIVS provides high-quality products at advantageous prices. By lowering costs and increasing efficiency, we ensure that our customers receive the best possible value for their investment.

4.Perfect After-sales Service

At SAIVS, we strive to provide superior customer service that meets and exceeds expectations. We are always available for any questions or concerns you may have, and we stand by our commitment to providing excellent after-sales support.

Related Posts

-

How important is temperature when you are Die Casting

Temperature control is a critical factor in die casting. The mechanical properties of the alloy, such as tensile and yield strengths, are negatively affect

-

About CNC precision machining

What is CNC precision machiningCNC precision machining is a type of manufacturing process that uses computer-controlled machines to remove material from a workp...

-

Benefits of Choosing Chinese Aluminum Die Casting Services

IntroductionAluminum die casting is a versatile and efficient manufacturing process that produces complex metal components with high precision and repeatab

-

Benefits Of 3D printing prototype

As technology evolves, 3D printing has become an important tool for improving prototyping in this industry through significant benefits such as precision and ef...

-

Infiltration, shaping, and repair of die-casting parts

1. Infiltration of die-casting partsInfiltration treatment is the process of immersing a die casting into a infiltration solution with infiltration and filling ...

-

Optimizing Tool Materials for Efficient Cast Iron Machining

In the competitive landscape of the machinery industry, improving processing technology and increasing efficiency are crucial for reducing overall costs. O