Choosing the Right Aluminum Alloy for Your Project

Author: SAIVS Date Published: Apr 11,2024

Aluminum's excellent formability makes it a versatile material for shaping into desired forms. Bending is a common technique, but different alloys and tempers have varying bendability. Here's what you need to know to pick the perfect one for your project.

Why Bending Aluminum is Useful?

Bending aluminum offers several advantages:

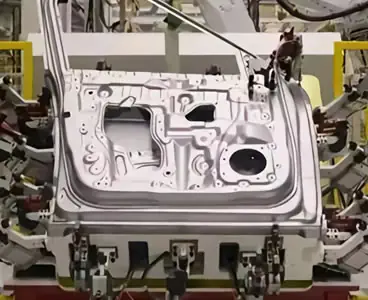

Design Flexibility: Achieve complex geometries and integrate functions into a single piece.

Cost-Effective: Bending is a simpler and cheaper process compared to other forming methods.

Aesthetics: Creates clean lines and a sleek look.

Variety of Bending Techniques: Choose from roller bending, press bending, draw bending, or stretch bending depending on your needs.

To maximize success, selecting the right alloy and temper alongside the bending method is crucial.

Factors Affecting Bendability

Three key factors influence an aluminum alloy's bendability:

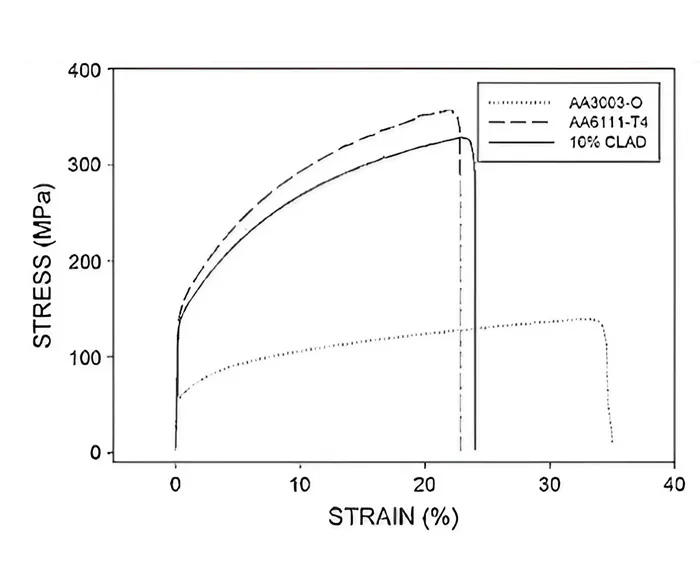

Formability: A trade-off exists between strength and ductility. Higher strength alloys are generally harder to bend.

Thickness and Bend Radius: Thicker materials and tighter bend radii require more force and are more prone to cracking.

Percentage Elongation: Higher elongation indicates better ability to deform plastically under tension, making bending easier.

Top Aluminum Alloys for Bending

Choosing the most suitable aluminum alloy for bending requires understanding two key factors: formability and strength. Here's a breakdown of three popular bendable alloys and why they excel:

Alloy 3003: This champion of bendability boasts excellent formability, making it ideal for bending without heat treatment. Its prevalence is evident in gutters, roofing, and siding.

Alloy 5052: Offering a good balance, 5052 combines moderate-to-high strength with good bendability. This makes it suitable for demanding applications beyond those suited for 3003. Additionally, its exceptional resistance to seawater corrosion allows it to shine in marine equipment.

Alloy 6061: The strongest of the three, 6061 boasts excellent strength that can be further enhanced through heat treatment. While its bendability is slightly lower, its strength makes it the most widely used aluminum alloy. Applications span from structural components to food containers and even bicycles.

These alloys showcase the versatility of bendable aluminum. Despite varying bendability, each offers unique strengths and applications:

3003: Unbeatable in bendability for intricate shapes.

5052: Strikes a perfect balance between bendability and strength.

6061: Prioritizes strength while retaining good bendability.

By understanding the factors affecting bendability and the strengths of popular bendable aluminum alloys, you can make an informed choice for your next bending project. Remember, the ideal combination of alloy, temper, and bending technique will ensure successful and beautiful results.

Why Choose SAIVS™ as Your Supplier?

1.Superb Quality Control Management

At SAIVS, we take pride in our perfect quality management systems and procedures, which guarantees the excellent performance of all our producs, being a professional Investment Casting | Die Casting| Sand Castingmanufacturer in China.

2.Rich Production Experience

With 20 years of experience in production, SAIVS has a deep understanding of the market and trends, and strives for continuous research and innovation. This has created advantages in both the product's performance and appearance.

3.Competitive Prices

As a Chinese factory committed to becoming the most cost-effective Investment Casting | Die Casting| Sand Castingexporter in China, SAIVS provides high-quality products at advantageous prices. By lowering costs and increasing efficiency, we ensure that our customers receive the best possible value for their investment.

4.Perfect After-sales Service

At SAIVS, we strive to provide superior customer service that meets and exceeds expectations. We are always available for any questions or concerns you may have, and we stand by our commitment to providing excellent after-sales support.

Related Posts

-

How Casting Simulation Improves Metal Casting Quality

Casting is a manufacturing process in which molten metal is poured into a mold and allowed to solidify. It is a versatile process that can be used to produce a ...

-

AN INNOVATIVE DIE CAST METHOD

AN INNOVATIVE DIE CAST METHODDoes your part design require external gears or threads where a parting line would significantly affect the part performance?We kno...

-

Forging and stamping: the current status of automobile stamping technology

The modern automotive industry demands ever-increasing production scale, multi-model compatibility, and large, integrated body panels. Traditional rigid, s

-

Die Casting Design Guide

AbstractDie casting, a high-pressure metal casting process is widely used in manufacturing industries for producing complex metal parts. This article delve

-

Rapid Injection Molding: A Guide to Fast-Track Production

Rapid injection molding offers fast, cost-effective production of plastic parts in low to medium volumes. Learn about the process, advantages, disadvantages, an...

-

Top 5 Precision Investment Casting Manufacturers

This article introduced the top 5 investment casting companies. If you have questions about your investment casting project, feel free to contact us today!