Benefits of Choosing Chinese Aluminum Die Casting Services

Author: SAIVS Date Published: Sep 02,2024

Introduction

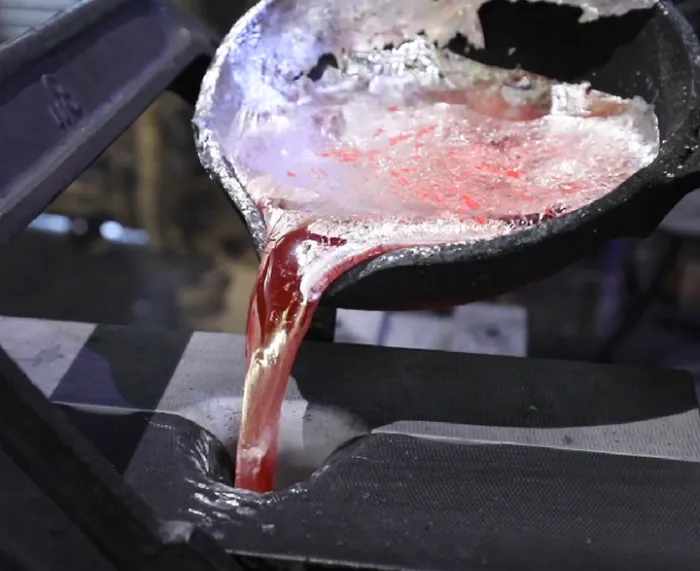

Aluminum Die Casting is a versatile and efficient manufacturing process that produces complex metal components with high precision and repeatability. China has emerged as a global leader in aluminum die casting, offering numerous advantages to manufacturers worldwide. This article explores the benefits of choosing Chinese aluminum die-casting services and provides insights on selecting the right partner for your project.

Advantages of Aluminum Die Casting

High production rates: Die casting offers exceptional production speeds, making it ideal for high-volume applications.

Complex part geometry: The process can produce intricate shapes and thin walls, enabling the creation of complex components.

Excellent dimensional accuracy: Die casting delivers components with tight tolerances and consistent quality.

Superior surface finish: Castings can be produced with a smooth surface finish, reducing the need for post-processing.

Material versatility: Aluminum alloys offer a wide range of properties, allowing for customization to specific application requirements.

Cost-effective: Die casting can be highly cost-effective, especially for large production volumes.

Why Choose Chinese Aluminum Die Casting Services?

Cost competitiveness: Chinese manufacturers offer competitive pricing due to lower labor costs and economies of scale.

Large manufacturing capacity: China has a vast manufacturing base equipped with state-of-the-art die-casting machines.

Experienced workforce: The country boasts a skilled workforce with extensive experience in aluminum die casting.

Complete supply chain: China offers a complete supply chain for aluminum die casting, from raw materials to finished products.

Customization and flexibility: Chinese manufacturers are adept at customizing solutions to meet specific customer requirements.

Factors to Consider When Choosing a Chinese Aluminum Die Casting Company

Experience and expertise: Look for a company with a proven track record in aluminum die casting and experience in your industry.

Quality Control: Ensure the company has robust quality control systems in place to meet industry standards.

Certifications: Consider companies with certifications such as ISO 9001 for quality management.

Equipment and technology: Assess the company's manufacturing capabilities and the technology they employ.

Capacity: Ensure the company can meet your production volume and delivery requirements.

Communication: Effective communication is crucial for a successful partnership. Choose a company that is responsive and transparent.

Partnering with saivs for Your Aluminum Die Casting Projects

Comprehensive solutions: We offer a one-stop solution for your engineering needs, from design and development to manufacturing and after-sales service.

Customization: Our flexible manufacturing capabilities allow us to tailor our products to your specific requirements.

Reliability: Our products are built to last, delivering exceptional performance and reliability.

Global reach: We serve customers worldwide, providing timely delivery and excellent customer support.

State-of-the-art facilities: Our 20,000+ square meter manufacturing facility is equipped with advanced CNC machining equipment, ensuring precision and efficiency in every product.

Skilled workforce: Our team of over 300 highly skilled professionals is committed to delivering exceptional products and services.

Quality assurance: We adhere to rigorous quality standards, as evidenced by our ISO 9001, ISO 14001, OHSAS 18000, and CE certifications.

Customer satisfaction: We are dedicated to meeting and exceeding our customers' expectations through customized solutions and timely delivery.

Conclusion

China's aluminum die-casting industry offers a wealth of benefits, from cost-effectiveness to customization options. By carefully selecting a reliable and experienced partner, manufacturers can leverage these advantages to produce high-quality components efficiently and cost-effectively.

Why Choose SAIVS™ as Your Supplier?

1.Superb Quality Control Management

At SAIVS, we take pride in our perfect quality management systems and procedures, which guarantees the excellent performance of all our producs, being a professional Investment Casting | Die Casting| Sand Castingmanufacturer in China.

2.Rich Production Experience

With 20 years of experience in production, SAIVS has a deep understanding of the market and trends, and strives for continuous research and innovation. This has created advantages in both the product's performance and appearance.

3.Competitive Prices

As a Chinese factory committed to becoming the most cost-effective Investment Casting | Die Casting| Sand Castingexporter in China, SAIVS provides high-quality products at advantageous prices. By lowering costs and increasing efficiency, we ensure that our customers receive the best possible value for their investment.

4.Perfect After-sales Service

At SAIVS, we strive to provide superior customer service that meets and exceeds expectations. We are always available for any questions or concerns you may have, and we stand by our commitment to providing excellent after-sales support.

Related Posts

-

How Casting Simulation Improves Metal Casting Quality

Casting is a manufacturing process in which molten metal is poured into a mold and allowed to solidify. It is a versatile process that can be used to produce a ...

-

Aluminum Gravity Casting vs. Other Methods: Choosing the Right Fit for Your Needs

Aluminum gravity casting is a metal casting process also known as aluminum alloy gravity casting or aluminum gravity ingot casting. In this process, molten

-

Differences between Die Casting and Investment Casting

What does investment casting mean?Investment casting is also called lost wax casting or dewaxed casting. Making parts by investment casting is usually a more ti...

-

how to replace the brake wheel cylinder and casting technology?

The brake wheel cylinder (commonly known as the brake caliper) is a very important component in the braking system. If it fails, it will have a great impact on ...

-

Technical Requirements for Investment Casting

Throughout the production process, precision casting solidifies its liquid immediately at room temperature and pours the compound into its unique die casting di...

-

High-Precision Shell Die Casting with ProCAST Optimization

At Ningbo SAIVS Machinery Co., Ltd, we take pride in being a trusted and experienced manufacturer of precision aluminum die cast components, offering custo