Aluminum CNC vs Stainless Steel CNC: What Are The Differences

Author: SAIVS Date Published: Dec 07,2023

Introduction

stainless steel and aluminum are two of the most common materials used in CNC machining.

Both materials have their unique advantages and disadvantages, making them suitable for different applications.

In this article, we will compare stainless steel and aluminum in terms of weight, cost, durability, range of applications,

thermal conductivity, and machinability. We will then conclude with a discussion of which material is more suitable for CNC machining.

Weight

Stainless steel is significantly heavier than aluminum. A cubic inch of stainless steel weighs about 0.28 pounds,

while a cubic inch of aluminum weighs about 0.09 pounds. This difference in weight can be a significant factor in

applications where weight is a concern, such as aerospace or automotive manufacturing.

Cost

Stainless steel is typically more expensive than aluminum. The cost of stainless steel can vary depending on the grade,

but it is generally about twice as expensive as aluminum.

Durability

Stainless steel is more durable than aluminum. It has a higher tensile strength,

which means it can withstand more stress without breaking. Stainless steel is also more resistant to corrosion,

which makes it a good choice for applications where the material will be exposed to harsh environments.

Range of applications

Both stainless steel and aluminum can be used in a wide range of applications.

Stainless steel is often used in applications where strength, durability,

and corrosion resistance are important, such as food processing, medical devices, and industrial equipment.

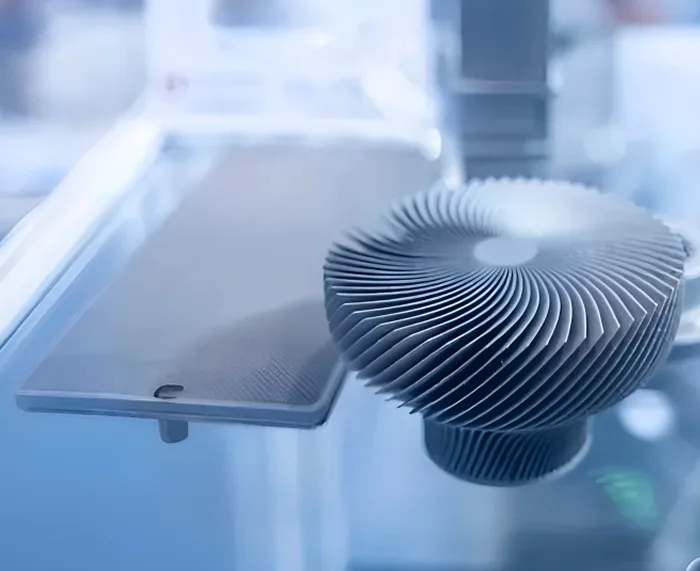

Aluminum is often used in applications where weight, cost,

and machinability are important, such as aerospace, automotive, and consumer electronics.

Thermal conductivity

Stainless steel has a higher thermal conductivity than aluminum.

This means that stainless steel can dissipate heat more efficiently than aluminum.

This can be a benefit in applications where heat dissipation is important, such as heat sinks and cooling systems.

Machinability

Aluminum is generally easier to machine than stainless steel.

This is because aluminum has a lower hardness and is more forgiving of errors.

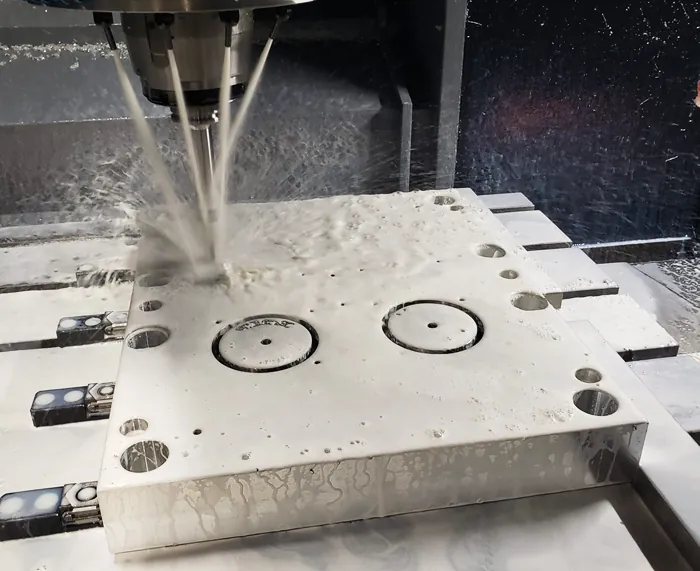

Stainless steel is more difficult to machine because it is harder and more brittle.

This can lead to increased tool wear and scrap rates.

Which material is more suitable for CNC machining?

The answer to this question depends on the specific requirements of the application.

In general, stainless steel is a good choice for applications where strength,

durability, and corrosion resistance are important.

Aluminum is a good choice for applications where weight, cost, and machinability are important.

Conclusion

| Stainless Steel | Aluminum | |

| Weight | Heavy | Light |

| Cost | twice as expensive as aluminum | Inexpensive |

| Durability | higher tensile strength | less durable |

| Range of applications | food processing, medical devices and industrial equipment | aerospace, automotive and consumer electronics |

| Thermal conductivity | high | low |

| Machinability | harder and more brittle | lower hardness |

Related articles:

①Process of CNC Rapid Prototyping

②How to Maximize the Efficiency of CNC Machining

③CNC Machining Tolerance Guidelines

Why Choose SAIVS™ as Your Supplier?

1.Superb Quality Control Management

At SAIVS, we take pride in our perfect quality management systems and procedures, which guarantees the excellent performance of all our producs, being a professional Investment Casting | Die Casting| Sand Castingmanufacturer in China.

2.Rich Production Experience

With 20 years of experience in production, SAIVS has a deep understanding of the market and trends, and strives for continuous research and innovation. This has created advantages in both the product's performance and appearance.

3.Competitive Prices

As a Chinese factory committed to becoming the most cost-effective Investment Casting | Die Casting| Sand Castingexporter in China, SAIVS provides high-quality products at advantageous prices. By lowering costs and increasing efficiency, we ensure that our customers receive the best possible value for their investment.

4.Perfect After-sales Service

At SAIVS, we strive to provide superior customer service that meets and exceeds expectations. We are always available for any questions or concerns you may have, and we stand by our commitment to providing excellent after-sales support.

Related Posts

-

Benefits Of 3D printing prototype

As technology evolves, 3D printing has become an important tool for improving prototyping in this industry through significant benefits such as precision and ef...

-

Preventing Flow Lines in Injection Molding

Flow lines, visible as streaks or wave-like patterns on the surface of molded parts, are a common aesthetic defect in injection molding. Although they typi

-

The Six Key Benefits of Lost Foam Casting

In the ever-evolving landscape of manufacturing, selecting the right casting method is crucial for efficiency and cost-effectiveness. Lost foam casting has

-

Advantages and precautions of aluminum alloy gravity casting?

The thickness of the outer wall of aluminum alloy castings in the process of gravity casting is called wall thickness, which is an important factor in the proce...

-

Forging vs. Machining: A Comprehensive Comparison

Forging and machining are two fundamental industrial processes that shape and manufacture metal parts. Each process has advantages and disadvantages, makin

-

Influence of Metal Forging Process on Part Quality

Through the analysis of forging defects, this paper puts forward suggestions for optimising the forging process, aiming to improve the quality of forgings.