Aluminum Alloy Die-Casting Molds:How To Extend Service Life

Author: SAIVS Date Published: Nov 27,2023

Extending the service life of die-casting molds is of utmost importance due to several reasons:

1. Cost Efficiency:

Die-casting molds are a significant investment in the Manufacturing Process.

By extending their service life, companies can maximize their return on investment and minimize

the need for frequent mold replacements. This leads to cost savings in terms of mold procurement,

production downtime, and overall operational expenses.

2. Enhanced Productivity:

A longer mold service life translates to increased productivity.

When molds are in good condition, they can consistently produce high-quality castings without interruptions.

This reduces production downtime and improves overall Manufacturing Efficiency.

3. Consistency in Product Quality:

Die-casting molds that are properly maintained and have an extended

service life contribute to consistent product quality. They help maintain precise dimensions,

surface finish,and other critical specifications of the castings.

This is particularly crucial in industries where uniformity and precision are essential.

4. Reduced Scrap and Rework:

Damaged or worn-out molds can result in defective castings, leading to increased scrap rates and the need for rework.

By extending the mold service life, the occurrence of defects can be minimized, reducing scrap and rework costs.

5. Time Savings:

Mold replacement or repair can be a time-consuming process that halts production.

By extending the service life of molds, companies can avoid frequent mold changes

and reduce the time spent on mold maintenance or repairs.

This allows for uninterrupted production schedules and faster time-to-market for products.

How to extending the service life of die-casting molds

Utilizing Mold Cooling System

One of the most effective ways to extend the service life of a Die Casting mold is by using a mold cooling system.

It helps improve the mold's lifespan and enhances production efficiency. Maintaining the proper temperature

is crucial because die steel has limited tolerance for high temperatures.

Using the mold at high temperatures can easily result in cracks on the mold core's surface.

Additionally, high temperatures can cause the color of the mold core to change and

excessive utilization of release agents. By implementing a cooling water system,

the excessive use of release agents can be minimized. This not only extends the mold's

service life but also helps maintain the quality of the casted products.

Preheating the Mold

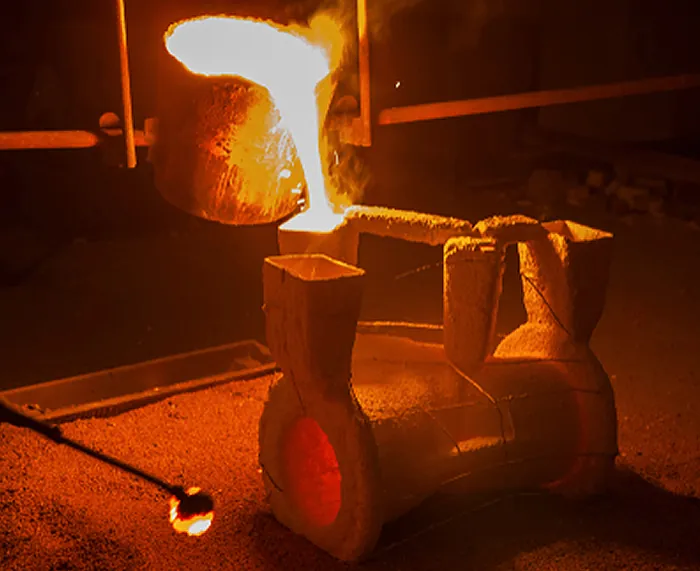

Preheating the mold is another technique that can increase its lifespan. Cracks often occur when hot molten

metal is poured into the mold due to a rapid temperature exchange.

Preheating the mold helps prevent the formation of cracks during this process.

For molds with complex designs, it is recommended to preheat them using a blowtorch or gas.

On the other hand, a slow press shot is suitable for molds with simple designs, as preheating

prepares the mold surface to withstand the high temperatures of the molten metal.

Maintenance of Signal Line

If the mold has an inbuilt neutron flux measuring system, it is important to prevent any contact between

the signal line and the die casting machine. During the production process, short-circuiting can occur

due to the signal line coming into contact with water or the breakage of the contactor.

Faulty signals can damage the mold, causing alarms and automatic stoppages, resulting in time loss or chaotic signals.

In conclusion

Extending the service life of die-casting molds is crucial for cost efficiency,

enhanced productivity, consistent product quality, reduced scrap and rework, and time savings.

By implementing techniques such as utilizing a mold cooling system, preheating the mold,

and maintaining the signal line, companies can prolong the lifespan of their molds and reap

the benefits of improved Manufacturing processes. Investing in proper mold maintenance and optimization

not only saves costs but also ensures the production of High-quality castings and a competitive edge in the industry.

Why Choose SAIVS™ as Your Supplier?

1.Superb Quality Control Management

At SAIVS, we take pride in our perfect quality management systems and procedures, which guarantees the excellent performance of all our producs, being a professional Investment Casting | Die Casting| Sand Castingmanufacturer in China.

2.Rich Production Experience

With 20 years of experience in production, SAIVS has a deep understanding of the market and trends, and strives for continuous research and innovation. This has created advantages in both the product's performance and appearance.

3.Competitive Prices

As a Chinese factory committed to becoming the most cost-effective Investment Casting | Die Casting| Sand Castingexporter in China, SAIVS provides high-quality products at advantageous prices. By lowering costs and increasing efficiency, we ensure that our customers receive the best possible value for their investment.

4.Perfect After-sales Service

At SAIVS, we strive to provide superior customer service that meets and exceeds expectations. We are always available for any questions or concerns you may have, and we stand by our commitment to providing excellent after-sales support.

Related Posts

-

Cold Forging And Hot Forging:What Is The Difference

Forging is a widely used manufacturing process that involves shaping metal by applying compressive forces.Two primary methods of forging are hot forging and col...

-

The benefits of sand mouldings in aluminium casting

The benefits of sand mouldings in aluminium castingSand casting is a very popular casting process, primarily because of the many benefits sand mouldings offer t...

-

What Is Sand Casting And Its Process

What is sand casting?Sand casting is a metal casting process that uses sand to create the mold in which the metal is poured. It is the most common casting proce...

-

Aluminum: A Versatile Metal with a Duality in Spelling

Aluminum is a versatile metal with a wide range of applications. This article will discuss the history of aluminum, its properties, and its applications.

-

Why is Stainless Steel Difficult to Machine

In this article, we will explore the main reasons why stainless steel is challenging to machine, including high cutting forces and temperatures and accelerated ...

-

Network Burrs in Aluminum Alloy Die Casting

Learn how optimizing die design, controlling temperatures, adjusting fill speeds, and improving cooling systems can enhance casting quality and production effic...