A Comprehensive Guide to Customized Food Machinery Parts: Manufacturers, Suppliers, and Prices

Author: SAIVS Date Published: May 22,2023

People are often interested in a variety of parameters and information when searching for Food Machinery Parts that are Customized, factory-made, and available from manufacturers and suppliers at competitive prices. Some of the most common questions people have include:

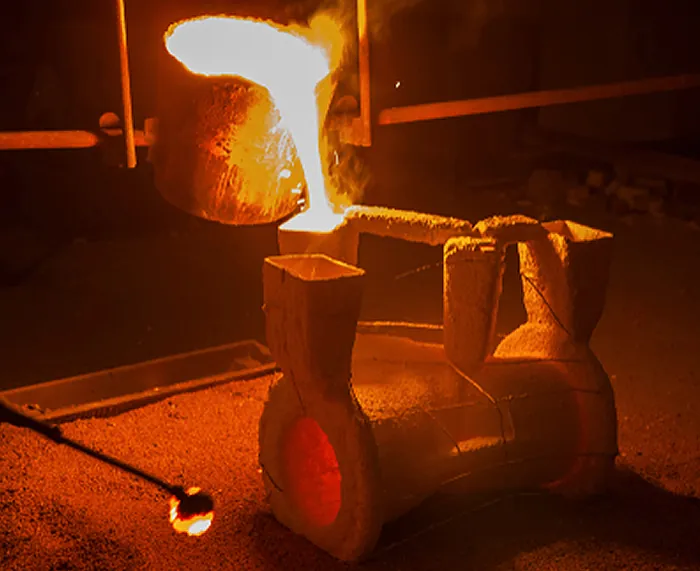

stainless steel investment casting food industry parts

What types of Food Machinery Parts are available for customization?

How long does it take to receive customized parts from the factory?

Are there any minimum order requirements for customized Food Machinery Parts?

Can the supplier provide samples or references for previous orders?

What materials are used in the manufacturing process, and are they FDA- or EU-approved?

What is the warranty on custom-made Food Machinery Parts?

What are the payment terms and methods accepted by the manufacturer or supplier?

To answer these questions, it is important to research the various options available on the market. Different factories and suppliers may specialize in different types of Food Machinery Parts, such as conveyors, mixers, filling machines, packaging equipment, and more. They may also have different lead times and minimum order quantities, so it is essential to clarify these details ahead of time.

When looking for custom-made Food Machinery Parts, it can be helpful to ask for samples or references from other clients who have had similar parts made. This can give a better sense of quality, durability, and reliability of the supplier's work.

In terms of materials, many Food Machinery Parts are made from stainless steel or food-grade plastic, but the specific grade and certification can vary depending on the type of part and its intended use. It is important to ensure that the supplier complies with relevant regulations and standards before placing an order.

Finally, payment terms and methods are another important consideration. Many manufacturers and suppliers accept bank transfers or credit card payments, but some may also offer other options like PayPal or Alibaba Trade Assurance. It is important to clarify all of these details before finalizing an order to avoid any misunderstandings or delays.

Why Choose SAIVS™ as Your Supplier?

1.Superb Quality Control Management

At SAIVS, we take pride in our perfect quality management systems and procedures, which guarantees the excellent performance of all our producs, being a professional Investment Casting | Die Casting| Sand Castingmanufacturer in China.

2.Rich Production Experience

With 20 years of experience in production, SAIVS has a deep understanding of the market and trends, and strives for continuous research and innovation. This has created advantages in both the product's performance and appearance.

3.Competitive Prices

As a Chinese factory committed to becoming the most cost-effective Investment Casting | Die Casting| Sand Castingexporter in China, SAIVS provides high-quality products at advantageous prices. By lowering costs and increasing efficiency, we ensure that our customers receive the best possible value for their investment.

4.Perfect After-sales Service

At SAIVS, we strive to provide superior customer service that meets and exceeds expectations. We are always available for any questions or concerns you may have, and we stand by our commitment to providing excellent after-sales support.

Related Posts

-

Rethinking Quenching: The Potential of Water in Modern Heat

Introduction:Quenching oil has long been the preferred cooling medium in heat treatment processes due to its unique cooling characteristics. However, conce

-

Nickel-Based Alloy Casting: Superior Corrosion Resistance

What is Nickel-Based Alloy Casting?Nickel-based alloys are metallic materials that primarily consist of nickel,but they also include various other elements such...

-

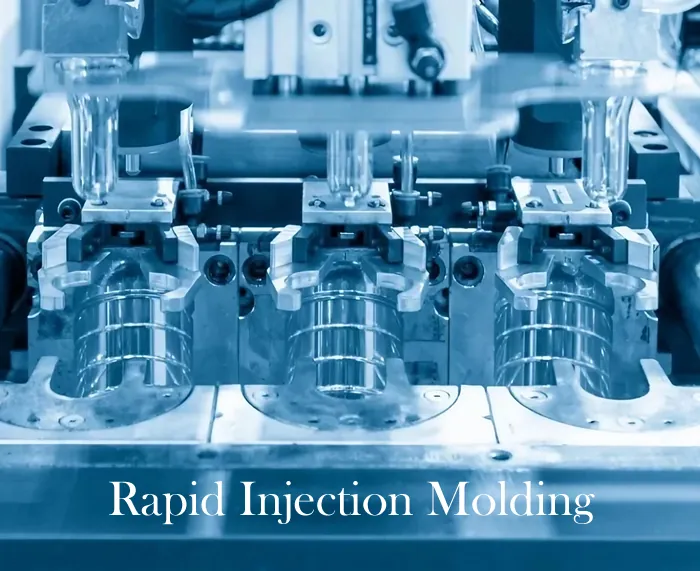

Rapid Injection Molding: A Guide to Fast-Track Production

Rapid injection molding offers fast, cost-effective production of plastic parts in low to medium volumes. Learn about the process, advantages, disadvantages, an...

-

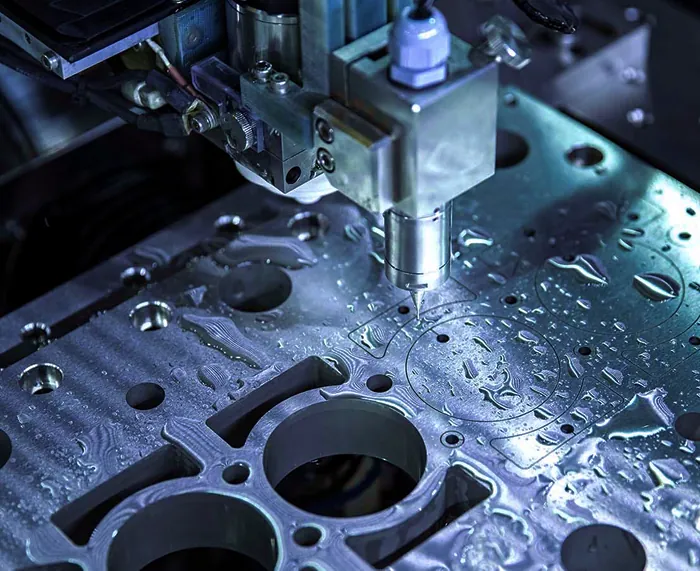

Die cast product design: 3 considerations

Die casting is a manufacturing process used to produce metalcomponents with high precision and efficiency. It involves injecting molten metal into a die, which ...

-

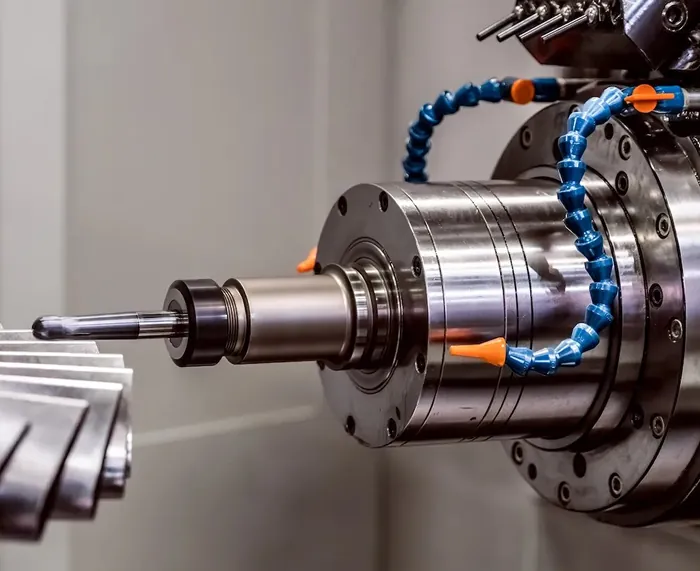

5 CNC Machining Materials

AluminumAluminum is one of the most popular materials for CNC machining due to its excellent machinability, lightweight nature, and resistance to corrosion

-

Aluminum Alloy Die-Casting Molds:How To Extend Service Life

Extending the service life of die-casting molds is of utmost importance due to several reasons:1. Cost Efficiency: Die-casting molds are a significant investmen...