Brief analysis of the characteristics and advantages of aluminum die casting

Author: SAIVS Date Published: Apr 28,2023

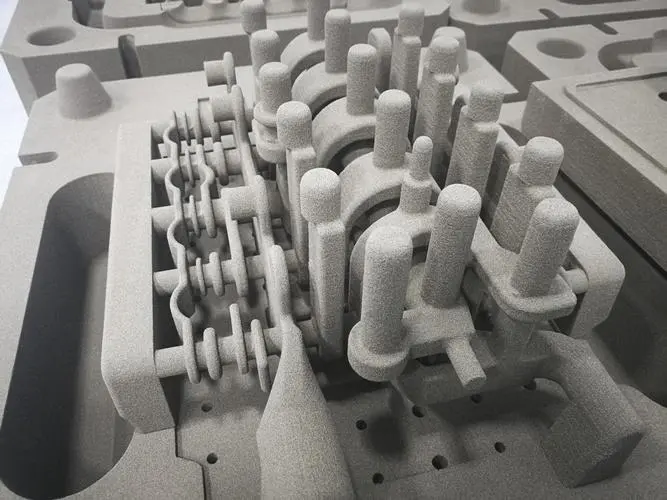

822719.jpg)

Briefly analyze some characteristics and advantages of Aluminum Die Casting.

aluminum die casting is a very popular manufacturing method in the process of production. It has many benefits to a certain extent. Many manufacturers and consumers will choose to use its aluminum die casting.

Features and advantages of aluminum die casting

1. Aluminum die casting has few internal pores during the production process, and heat treatment can be carried out during use. After heat treatment, the strength of the product can be greatly improved, even exceeding that of die-casting products.

2. The product has low density. Relying on liquid self-weight molding, the compactness of the product is lower than that of die-casting, and its strength is also slightly lower, but its elongation is higher.

3. The surface finish of the product is not high. After cooling and shrinkage, the surface of the casting product is easy to form pits similar to skimming.

4. Filling is slow and production efficiency is low. Its production efficiency is only about a quarter of that of high-pressure casting, resulting in high product costs.

5. Mold life is longer than die casting. Low mold cost.

6. The process is relatively simple.

7. Not suitable for the production of thin-walled parts.

Why Choose SAIVS™ as Your Supplier?

1.Superb Quality Control Management

At SAIVS, we take pride in our perfect quality management systems and procedures, which guarantees the excellent performance of all our producs, being a professional Investment Casting | Die Casting| Sand Castingmanufacturer in China.

2.Rich Production Experience

With 20 years of experience in production, SAIVS has a deep understanding of the market and trends, and strives for continuous research and innovation. This has created advantages in both the product's performance and appearance.

3.Competitive Prices

As a Chinese factory committed to becoming the most cost-effective Investment Casting | Die Casting| Sand Castingexporter in China, SAIVS provides high-quality products at advantageous prices. By lowering costs and increasing efficiency, we ensure that our customers receive the best possible value for their investment.

4.Perfect After-sales Service

At SAIVS, we strive to provide superior customer service that meets and exceeds expectations. We are always available for any questions or concerns you may have, and we stand by our commitment to providing excellent after-sales support.

Related Posts

-

How to improve the quality of gear forgings

How to improve the quality of gear forgings? Shanghai Zhiyuan Flange Forging Co., Ltd. pointed out that hardness is an important quality inspection index for he...

-

Comparison of Silica Sol and Water Glass in Precision Casting

This article will explore the characteristics, applications, and advantages of Silica Sol and Water Glass, providing a comprehensive understanding of their role...

-

Choosing the Right Stainless Steel Forging Manufacturer: Key Factors to Consider

Discover applications (construction, medical) and qualities of a good supplier (expertise, customization).

-

The Effective Uses of Sand Casting for Construction Machinery Parts

The construction machinery industry requires the production of big parts that have shapes, sizes, and complexities that are not easy to produce by conventional ...

-

Infiltration, shaping, and repair of die-casting parts

1. Infiltration of die-casting partsInfiltration treatment is the process of immersing a die casting into a infiltration solution with infiltration and filling ...

-

Rethinking Quenching: The Potential of Water in Modern Heat

Introduction:Quenching oil has long been the preferred cooling medium in heat treatment processes due to its unique cooling characteristics. However, conce