Ningbo saivs machinery co., Ltd. is a leading provider of high-quality castings and CNC machining services,We have a complete quality management system in place, and our facility is ISO 9001:2015 and ISOTS16949 certified for quality.

SAIVS carry out three types of inspections at different stages of the manufacturing project;

Inspection by the machine operator

here, the operator carries out various article inspections during (or immediately) after machining to identify tolerance problems. It involves using simple measuring tools such as go/no-go gauges and micrometers.

Inspection via in-process probing

describes an automated way of verifying key features and tolerances of a part during the CNC machining process using programmed probes. These probes automatically monitor the process and adjust work coordinates and cutting tools accordingly.

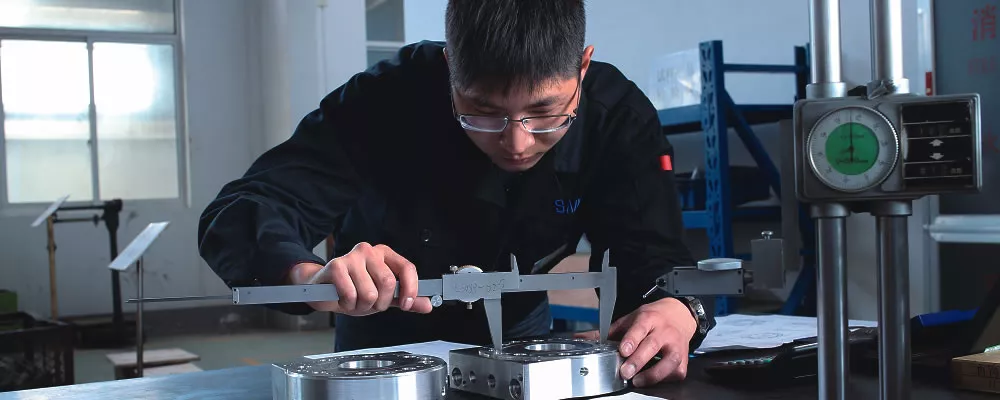

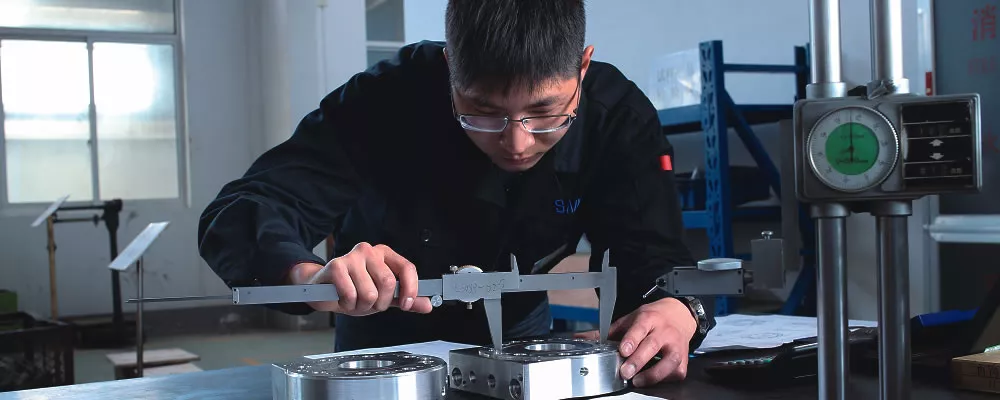

Inspection in the Quality Control (QC) department

it describes the inspection stage carried out on CNC machined parts by a team of quality control experts. These QC experts utilize height gages, microscopes, 2D projectors, micrometers, and coordinate measuring machines (CMM) to ensure that parts conform to the customers’ requirements. The picture above shows one of our QC team members at SAIVS operating a CMM machine.

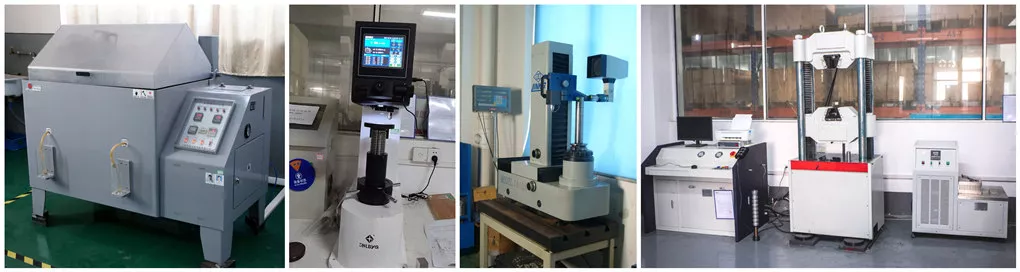

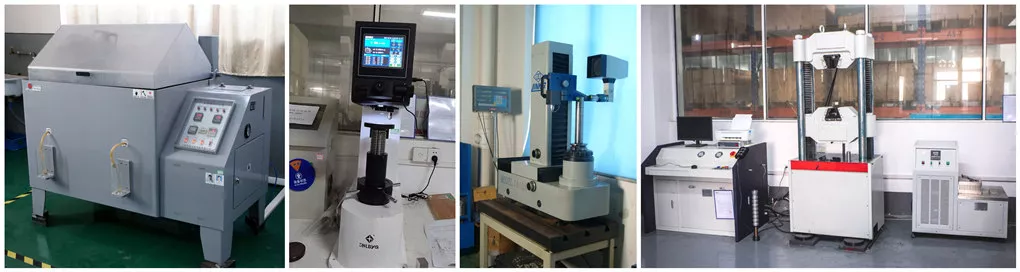

Quality control equipments list

Equipment name | Qty |

Spectrum analysis | 1 |

CMM | 2 |

300/150 impact machine | 1 |

Hydraulic universal testing machine | 1 |

Image projector | 1 |

Metallographic microscopy | 1 |

Digital display push-pull force meter | 1 |

Electronic digital display spring pressure testing machine | 1 |

Motorized surface Rockwell hardness tester | 1 |

Rockwell hardness tester | 1 |

Brinell hardness tester | 1 |

Surface roughness tester | 1 |

Shore hardness tester | 1 |

Portable Brinell hardness tester | 1 |

Portable Brinell hardness tester | 1 |

Direct read optical spectrum analyzer | 1 |