High Quantity Production Forging Solutions

Forging is the manufacturing process of hammering, pressing or rolling metal into shape. This is either delivered from a hammer, press or die. It is essentially the art of heating and working hot metal to design or shape that is fit for a specific purpose or use. By working the material, it increases many of its properties, including structure, conductivity and longevity. Forging offers a very useful and diverse medium for many industries with the process being economically sound and achieving specific mechanical properties. Forging is often categorized according to the temperature at which it is performed, cold, warm, or hot forging.

Forging material scope

stainless steel: SS201,SS301,SS303, SS304, SS316, SS416 etc.

Steel: mild steel, Carbon steel, 4140, 4340, Q235, Q345B, 20#, 45# etc.

Brass: HPb63, HPb62, HPb61, HPb59, H59, H68, H80, H90 etc.

Copper : C11000,C12000,C12000, C36000 etc.

Aluminium: AL6061, Al6063, AL6082, AL7075, AL5052, A380 etc.

Iron: A36, 45#, 1213, 12L14, 1215 etc.

Capabilities of forging

1. High Precision, New Technology, Competitive Price for Forging and machining

2. Advanced Forging machines available.

3. All kinds of facility, CNC machining, turning, milling, tapping, drilling, polishing, punching, etc...

4. Competitive Prices, Excellent Service, and Good Lead Time.

5. 100% full inspection before shipment.

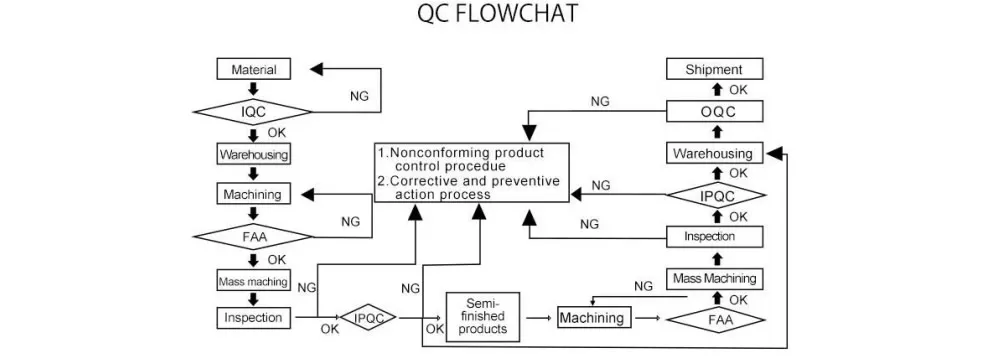

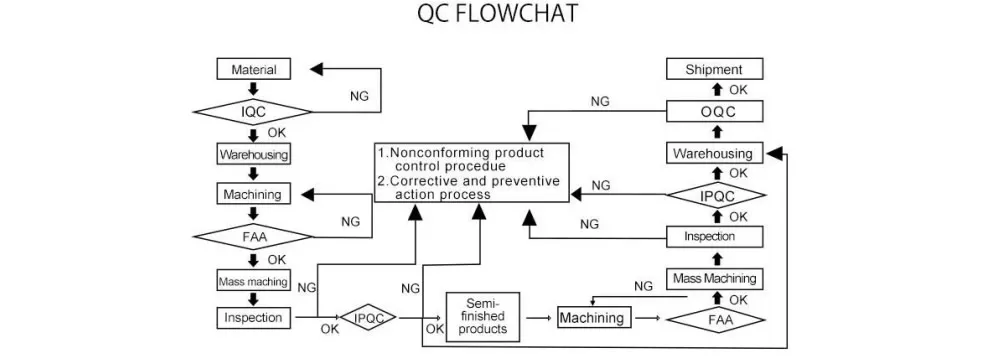

Inspection Capabilities and Quality Control programs

CMM (Coordinate Measuring Machine)

spectrum analysis and manual quantitative analysis

Metallographic analysis

Brinell, Rockwell and Vickers hardness inspection

Mechanical property analysis

Low and normal temperature impact testing

Cleanliness inspection

UT, MT and RT inspection

APQP PPAP FMEA quality control programs

Applications of forging Components

1. Construction: lifting anchors for precast concrete, spherical head anchors

2. Automotive industry: piston, connecting rods, cams, camshafts, crankshafts

3. Heavy machinery: Rock breaker, excavator parts

4. Energy: Anvil, gate valve, wellhead control EQP, wellhead EQP

5. Defense: Black receiver, aluminum trigger guards and receivers

6. Truck: Cylinder heads, oil sump, clutch housing, front and rear brake calipers.

Value Added Services

Heat treatment: Quenching, Tempering, Normalizing, Annealing, Carburization, Nitration

Surface treatment: Anodizing, Zinc-plating, Polising, GeoMet, Zintek, Electrophoresis....etc

Testing Service: Chemical Composition, Mechanical Properties, Fluorescent or Magnetic Penetration Inspections (FPI, MPI), X-rays, Ultrasonic Testing, Dynamic and Static Balancing Testing

OEM/ODM Service

OEM/ODM service are welcomed, we have great advantage in R&D, assembly of mechanical components, we have more than 10 engineers and technicians, with many years of experience in working with our customers worldwide for designing and testing, we are view as a reliable partner due to the level of experience and expertise offered in the development, design and commercial support for our customers’ products. Any formats of Stp, Step, Igs, Xt, AutoCAD(DXF, DWG), PDF drawing are welcomed

Contact SAIVS For Forging Services

SAIVS is the top custom Forging manufacturer in China. We can supply all kinds of different Forging parts in steel, iron, aluminum, etc.You can send your detail RFQ and drawings to us via e-mail.

Request a Quote