What is Aluminium Gravity Casting?

Aluminium Gravity Casting is a permanent mould casting process, where the molten metal is poured from a vessel or ladle into the mould. The mould cavity fills with no force other than gravity, filling can be controlled by tilting the die. Undercuts, and cavities can be incorporated into the component form with the use of sand cores. This process gives a better surface finish than Sand Casting as well as better mechanical properties, both due to rapid solidification.

Additionally, this process has a higher casting rate than aluminium sand casting, however, the metal moulds are a higher cost than sand. Advantages of this process include the possibility of low gas porosity, and fine grain sizes can be achieved.

Compared to sand casting, this process requires less finishing and fettling and gravity Die Casting tends to produce a higher quality product. The Gravity die casting production method is generally less cost effective in the manufacture of tooling compared with sand casting.

ASMT Standard: A319, A356, A357, A413

GB Standard: ZL101, ZL101A, ZL102, ZL107

BS Standard: LM6, LM20, LM25

EN Standard: EN AC-42100, EN AC-42200, EN AC-43000, EN AC-43200, EN AC-43300, EN AC-43400, EN AC-44200, EN AC-44300, EN AC-46000, EN AC-46200

Capabilities of Aluminium Gravity Casting

Our manufacturing capacity for aluminum from 0.5 to 30 kg to various industries, especially for aluminum gravity die casting process, we use state-of-the-art casting process and secondary machining capabilities. We have offer the volume added service like powder coating, anodizing, painting, and assembly.

Capabilities of die Casting product

Weight Range of die Castings: 0.5 kg - 20 kg

Annual Capacity of Sand Castings: 1,000 tons - 3,000 tons

Casting Tolerances: On Request or According to ISO 8062

saivs is a leading casting foundry in China of top-quality Aluminium Gravity Casting committed to delivering excellent quality, superior value and exceptional customer experience. SAIVS has the experience, technical expertise and quality assurance processes to consistently and reliably deliver an extensive range of precision castings with further processing.

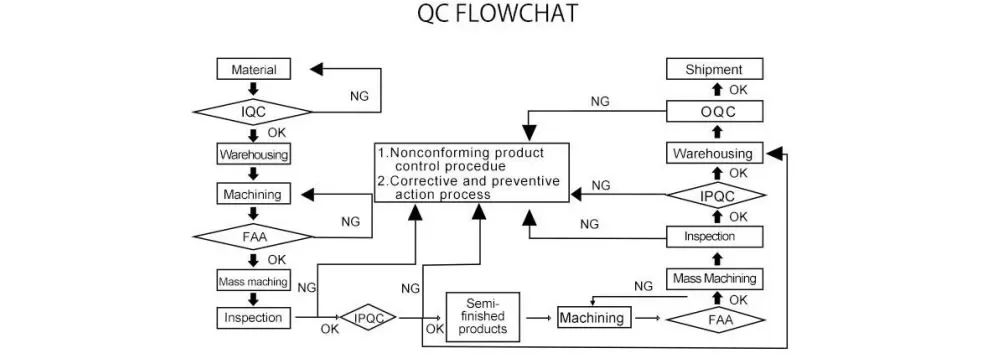

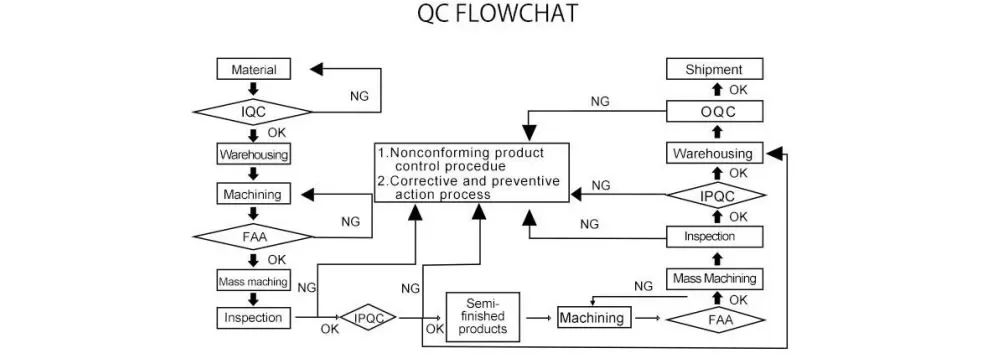

Inspection Capabilities and Quality Control programs

Spectrographic and manual quantitative analysis

Metallographic analysis

Brinell, Rockwell and Vickers hardness inspection

Mechanical property analysis

Low and normal temperature impact testing

Cleanliness inspection

UT, MT and RT inspection

APQP PPAP FMEA quality control programs

Pressure Testing – up to 2000 kPa or 290 psi.

Applications of Aluminium Gravity Casting Components

SAIVS offers advanced aluminum gravity die casting solutions tailored to meet the high-performance needs of multiple industries. This casting method provides excellent dimensional accuracy, high mechanical strength, and superior surface finishes, making it ideal for producing complex and durable components.

In the automotive industry, our aluminum castings are widely used for engine parts, suspension systems, intake manifolds, and more. The lightweight and high-strength properties of aluminum help reduce vehicle weight and enhance fuel efficiency, while also lowering post-machining costs through tight tolerance capabilities.

For the marine sector, we deliver corrosion-resistant aluminum cast components such as propeller blades, engine blocks, and pump housings—ensuring safety and reliability even in harsh environments.

In the lighting industry, SAIVS produces long-lasting, weather-resistant parts like heat sinks and streetlight housings, offering both functional and aesthetic benefits.

Our casting solutions also serve the agriculture sector, delivering precise components like gearbox housings and pump bodies for modern farming equipment.

With custom capabilities and a commitment to quality, SAIVS is your trusted partner for aluminum gravity die casting. contact us to learn how we can support your next project with efficient, high-performance aluminum parts.

Value Added Services

Heat treatment: Quenching, Tempering, Normalizing, Annealing, Carburization, Nitration

Surface treatment: Anodizing, Zinc-plating, Polising, GeoMet, Zintek, Electrophoresis....etc

Testing Service: Chemical Composition, Mechanical Properties, Fluorescent or Magnetic Penetration Inspections (FPI, MPI), X-rays, Ultrasonic Testing, Dynamic and Static Balancing Testing

OEM/ODM Service

OEM/ODM service are welcomed, we have great advantage in R&D, assembly of mechanical components, we have more than 10 engineers and technicians, with many years of experience in working with our customers worldwide for designing and testing, we are view as a reliable partner due to the level of experience and expertise offered in the development, design and commercial support for our customers’ products. Any formats of Stp, Step, Igs, Xt, AutoCAD(DXF, DWG), PDF drawing are welcomed

Contact SAIVS For Aluminium Gravity Casting Services

SAIVS is the top custom Aluminium Gravity Casting manufacturer in China. We can supply all kinds of different Aluminium Gravity Casting parts in steel, iron, aluminum, etc.You can send your detail RFQ and drawings to us via e-mail.

Request a Quote